Wastewater Plant Start-Up and Seeding Solutions

Choosing an appropriate seeding method for starting up or restarting wastewater operations can have a significant impact on how quickly biological treatment is up and running properly. Activated sludge is traditionally used to seed and reseed treatment systems.

BioLynceus® products contain high concentrations of many types of bacteria for plant start-up and restart of a variety of biological treatment systems. BioLynceus® seed products are alive, ready to use in convenient drum or tote packaging that can be on-site, ready to go when you need it.

With BioLynceus®, there are neither complicated logistics nor risks of introducing chemicals or and unwanted species into your system.

Webinar – Plant Startup with Tanner Hartsock

Tanner Hartsock M.S. takes us through the process of starting a wastewater plant and considers different options operators have in solving their challenges.

What we didn’t expect was to get such a glowing endorsement from a client about our approach at the end.

Check out timestamp 18:24 where he starts with “The good thing about it is, we always keep … 1 or two buckets on hand … just in case we have an upset”

We’ve helped Mark solve several issues over the years, and we know that we can help you as well.

Wastewater System Restart or Initial Start Up?

In the world of wastewater these days there are many challenges that will occur. Some you may have already seen and some may appear in the near future. One of these many challenges is how to get your plant activated if it is killed off by known or un-known environmental issues. The reasons can vary from a crystal meth hit to someone dumping diesel in your line or some other toxic substance in your collection system. Sometimes these challenges are self-inflicted, by allowing septic or grease haulers to discharge to your system. And of course, there is the issue of chemicals that your collection people may be using to clean lines or kill roots.

Method for Start Up or Restart

The other scenario could be that you have just finished building that brand-new wastewater plant or addition. After spending millions of dollars to complete the new system, how do you get it started and working at optimal parameters as quickly as possible?

There are several options available to most wastewater systems, no matter what design you have. You can startup or reactivate activated sludge plants, BNR facilities, anaerobic digesters and lagoon systems, both aerated and facultative.

There are many accepted methods for a startup or restart. These include just letting the plant biology develop naturally. If this is the method you decide to use, the industry estimates are that the plant will be at maximum efficiency somewhere between 90 to 180 days. If you have a lot of time, this method will work. If you need to meet discharge limits quickly, this may not be the best method for you to use.

Considerations for Using Activated Sludge

Another method is to inoculate the system with activated sludge from a neighboring community. This method will work and industry estimates are that this will take between 30 and 90 days to reach full efficiency. There are a few things to consider when using this method of startup or restart.

1. You will be hauling wastewater sludge into your community.

2. The biology in the neighboring community may or may not have all the bacteria that you will need.

3. Every wastewater system has different inflow, so therefore the biology will be different. And if you have significant industrial users (SIU), the odds are your neighbor will not have what you need.

4. Your neighbor’s sludge may contain undesirable things like a lot of filamentous bacteria, “flushable” wipes, and other trash.

A Closer Look at Bioaugmentation

Bioaugmentation is another method being used to restart your system or to complete an initial startup of a new plant or system. This process requires purchasing commercially available microbial cultures for your plant. If you purchase a high quality, Species Rich Diversity (SRD) product, experts estimate your system may be fully online between 3 to 30 days. Most of the systems I have seen using this method take about 10 days to populate.

Now you should become aware of some of the differences in the available bioaugmentation products on the market, today. You want to look for products that have actual bacteria or microbial counts in them. You want to make sure that the product has large counts of colony forming unit (CFU) and a high Species Richness Diversity (SRD). Some products will only have one, two or three types of bacteria, while others may have dozens. You want to look for products with high SRD’s.

Remember, your system has lots of different materials in the inflow that need to be biodegraded, so you will need a variety of species to complete the work. You may see products with millions of CFUs per gallon or per milliliter. Make sure you do the math. Products with 100 million per milliliter actually have more bacteria than those that have 1 billion per gallon.

I always recommend that you use products that are in liquid form. Our experience is that most bacteria species do not handle dehydration well. Many of the states’ circuit riders and government agencies are now accepting bioaugmentation as a viable solution.

Products that do not have actual bacteria/microbes in them are considered biostimulants and will not inoculate your system with the new bacteria you may need.

Making the Right Choice

One or more of the systems or programs listed above will work for you. You need to decide which will best meet your needs. If you want a speedy recovery, then bioaugmentation with quality products, that meet or exceed the above criteria, could be your best solution. If funding is the most critical issue, then natural recovery may be your best solution, as long as you are not out of compliance.

If easy, reinoculation of your system is important, then bioaugmentation could be the preferred over hauling activated sludge. If you have easy access to activated sludge, that does not require extensive hauling, then this may be your choice.

In some cases, you may want to utilize a combination of methods.

For More Information

Rick Allen can be reached at 303-888-2008 and [email protected]. Herb Fancher can be reached at 970-481-6626 or [email protected]

©Article is copyright 2019 protected by Rick Allen, BioLynceus®

Startup Industrial Membrane Bioreactor Wastewater Plant

Industrial Membrane Bioreactor Plant 0.01 MGD

When starting up a wastewater plant, the biological seed used can influence future treatment efficiency and operational challenges. Domestic activated sludge seeding has potential to introduced unwanted biological and solids contaminants that can cause unpredictable treatment issues.

Whether the source plant was experiencing the same problems or not, varied plant conditions can shift microbial community dynamics to impair treatment efficiency. In addition to biomass instability, activated sludge can introduce large trash particulate and inorganic solids requiring mechanical removal.

Wastewater facilities seeking a clean, controlled startup can benefit from using bioaugmentation for plant seeding. Augmenting a system with intentionally cultured communities of wastewater bacteria can help eliminate uncontrolled treatment challenges that often follow inoculation with domestic activated sludge.

The following case study outlines the implications of using BioLynceus® ProBiotic Scrubber® II (PBII) seed in an industrial membrane bioreactor (MBR) plant startup.

Figure 1. Empty MBR plant aeration basins prior to startup with BioLynceus® microbiology.

An industrial cider mill in Pennsylvania was in production from August to November each year. During this time, the MBR on site was operated to treat 0.01 MGD

wastewater flows from the manufacturer.

After the production season was over, the wastewater plant was drained and cleaned in preparation for the next year. This plant required startup every summer when cider manufacturing began.

The MBR was originally started with activated sludge form a neighboring municipal plant. Startups with domestic activated sludge caused operational challenges for the facility, because the sludge introduced rags and trash into the system.

The unwanted domestic debris were impairing flow through the MBR mechanical

components. In need of a cleaner and more reliable seed, the wastewater management contacted BioLynceus® biological solutions.

PBII was inoculated at the influent to the plant to start biological processing in the MBR. This seed introduced live cultures of diverse wastewater bacteria to the system. Within two weeks of treatment, the cider mill wastewater plant was efficiently processing influent flows.

The effluent from the plant was in compliance with publicly owned treatment works permitting. Furthermore, the operations staff no longer needed to remove trash for the process to work efficiently.

A side benefit of using PBII was, the cider mill could now use the treated wastewater to irrigate their apple orchards. Seeding the MBR with domestic activated sludge limited the manufacturer’s wastewater reuse.

Overall, BioLynceus® cultures provided a clean startup method with less operational challenges than previous activated sludge seedings.

BioLynceus® ProBiotic Scrubber® II provides a clean and effective seed for MBR startup.

Startup of a 8.9 MGD Anaerobic Digester at a Sugar Refinery

Mechanical WWTP 8.9 MGD

Halfway through a sugar beet processing campaign (September through May) a Midwest refinery noticed something was wrong with their wastewater processing system.

The plant discharge was within limits for their NPDES permit parameters, but the chemical oxygen demand (COD) readings from their 8.9 million-gallon anaerobic digester were very different at the top, center, and bottom of the digester. The system engineer suspected the mixers were not operating properly.

Without functional mixing, the digester was unable to process the high COD wastewater from the refinery. To fix the problem, the facility’s processing and engineering team decided to repair the mixing blades in the digester at the end of the campaign.

The digester was emptied and cleaned in the process, which removed all active biology in the tank. After maintenance was completed, the anaerobic digester needed to be reseeded to begin properly processing high COD wastewater.

Initially, using activated sludge from a neighboring sugar refinery’s anaerobic digester was suggested to seed the repaired digester. This process would involve hauling thousands of gallons of activated sludge, an expense ranging between $70,000 and $100,000.

In addition to cost, seeding with activated sludge from another facility would be highly time consuming and risky. The sludge could introduce unknown foreign contaminates to the newly cleaned and repaired system.

This could cause unpredictable treatment issues in the future. The plant was seeking alternative options, which lead them to BioLynceus®. The team at BioLynceus® suggested reseeding with Probiotic Scrubber® II (PBII).

This live culture treatment would supply the digester with a diverse microbial community and give the company a more cost-effective, easier to transport, and more reliable solution.

PBII was added to the digestor in addition to the facility’s high strength COD wastewater to restart the digester. After four days of implementing PBII, consistent methane was being produced by the digester; indicating the microbiology was properly processing the influent COD.

Seeding the digester with PBII saved the refinery time and money, because sludge hauling was not necessary to restart the system.

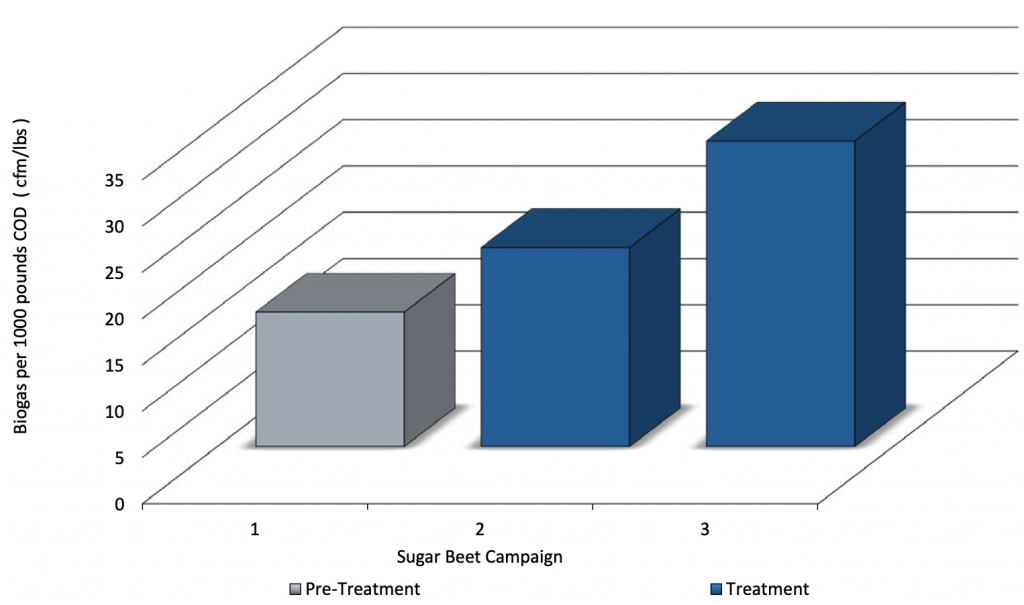

Figure 1. Cumulative biogas produced per 1000 pounds influent COD was calculated for an anaerobic digester at an industrial wastewater plant from November to March during three sugar refinery production campaigns. PBII was used to seed the anaerobic digester at the end of campaign 1. Treatment continued through campaigns two and three. The values displayed were calculated by summing the biogas produced divided by the COD loading.

An additional benefit of treating with PBII, was the quantity of methane produced was much higher than before treatment (Figure1). The average increase in biogas produced during the second and third campaign was 13 cfs per 1000 lbs COD.

These results were also attributed to cleaning out the digester and repairing the mixers before implementing the product. The methane produced was used as a cleaner energy source to help operate the drying kilns.

With BioLynceus®, the anaerobic digester was started with less financial burden than using activated sludge, and the biogas produced from the digester provides the refinery with a stable energy source.

BioLynceus® ProBiotic Scrubber®II is a cost-effective program for digestor start-up.

Startup of a Membrane Reactor

Mechanical WWTP .06 MGD

National parks attract millions of visitors each year. Increasing seasonal traffic experienced by these establishments can overload the wastewater treatment infrastructure leading to treatment inefficiency and, eventually, structural replacement.

When starting up a new plant, seeding with a healthy biomass is vital for instilling long-term treatment efficiency. The following case study outlines the startup of a membrane reactor (MBR) with Probiotic Scrubber® II (PBII) and small amounts of activated sludge.

Figure 1. Fully installed and operating Kubota MBR System. https:// www.kubota.com/products/solutions/

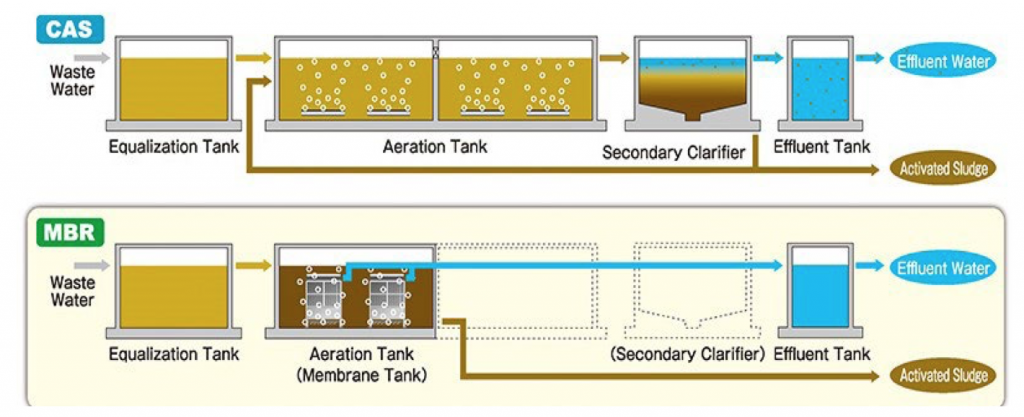

A national park in Wyoming was installing a new 0.06 MGD Kubota manufactured MBR system (Figure 1) to replace their old and overloaded conventional activated sludge (CAS) plant. The quantity of wastewater processed by the CAS plant continually increased each tourist season, May to October. The high flows generated by the transient populations at the park frequently overwhelmed the facility.

Specifically, during the summer, the mechanical plant received flows which well exceeded the small system’s treatment capacity. Because the volume of influent delivered to the CAS facility was beyond design specifications, the effluent quality was declining, and the facility operators were concerned with meeting their NPDES permit limits.

Figure 2. System diagrams comparing the treatment components of a CAS and MBR. The Kubota MBR does not require a secondary clarifier. MBR systems have greater treatment capacities with much smaller footprints. https://www.kubota.com/products/solutions/

The plant management decided their infrastructure needed to be replaced with a system which could handle higher flows (Figure 2). Designing and building the new MBR facility would take a minimum of two years. During that time, the current plant was required to meet permit limits.

The Utilities Supervisor at the Park contacted BioLynceus® to design a bioaugmentation plan to improve the biological treatment efficiency of their old system. The Park used PBII at their facility while the new MBR was constructed. PBII provided the biology needed to process high flows and keep the plant within permit compliance.

When the time came to startup the MBR facility, the management at the plant decided to use a combination of PBII and activated sludge to seed the reactor. Maintaining a high treatment efficiency was essential when starting up the new plant, so they opted to add PBII into the system from the beginning.

By adding BioLynceus® product, the plant reduced their sludge hauling costs, because they needed less activated sludge to start the reactor.

From startup, the MBR system was properly processing influent wastewater. Seeding the reactor with PBII was financially beneficial for the Park and helped to instill a biomass that promoted efficient treatment in their new system.

BioLynceus® ProBiotic Scrubber® II provides an effective biomass for MBR startup.

Startup Mechanical Plant After Failed Activated Sludge Seeding

Mechanical WWTP .7 MGD

Choosing an appropriate seeding method for wastewater operations can have a significant impact on biological treatment efficiency. Activated sludge is traditionally used to seed new treatment systems and supplement others that need bioaugmentation. A common issue in activated sludge systems is sludge bulking (SB), or the uncontrolled growth of filamentous bacteria (FB).1 Impacts of a bulking sludge include (but are not limited to) poor settleability, impaired biological nutrient removal, and increased facility maintenance.

Predicting whether SB will occur in a newly seeded wastewater process is difficult, because the FB in activated sludge respond differently to varying system conditions. One method to prevent bulking is to quantify the proportion of FB in activated sludge before inoculation. Previous studies have found that SB can occur in systems with a volume fraction of FB as low as 1-20%.

Even when filament forming organisms are in low abundance, they can still cause treatment issues. Bioaugmentation with a specifically designed microbial community can be a more reliable alternative to using activated sludge as seed. The following case study outlines the use of ProBiotic Scrubber® II (PBII) in a 0.7 MGD mechanical wastewater treatment plant (MWTP) to restore a healthy biomass after the plant was seeded with FB.

The wastewater from a small resort town in Colorado was processed at a mechanical plant with rotating bed contactors for nutrient removal. The plant was operating properly until a concentrated load of petroleum based toxic waste was introduced to the system.

The biological treatment was inhibited so severely by this event that the MWTP needed reseeding. To reinstate their plant biomass, the operators brought in activated sludge from a neighboring wastewater treatment facility and added several loads to the plant.

What the operators didn’t know was that they had seeded their system with FB that would cause issues in the future.

Shortly after inoculation, the plant was having troubles with foaming, solids settling, and continuously clogged filters. Facility personnel were scheduled around the clock just to keep up with backwashing the filters. After examining a mixed liquor sample from the plant, the head operator realized that FB accumulated in the reactor and were preventing solids and nutrient reduction from occurring.

They needed to decrease the abundance of these organisms to resume proper wastewater processing. The facility management contacted BioLynceus® to provide a bioaugmentation plan to reinstate a healthy biological community in the treatment system.

Figure 1. MWTF aeration basin after the PBII treatment with regular foam development.

BioLynceus® PBII was supplied to the aeration tank of the 0.7 MGD system. Twenty-four hours after PBII was applied, nitrification was restored in the basin. Suspended solids were gradually reduced in the plant effluent over several weeks. This indicated that the biology in the facility was shifting to a more desirable composition; one that was allowing settling to occur.

Foaming was also reduced in the aeration basin to normal amounts (Figure 1). The operators were relieved to see such an improvement in their biological treatment, because they had to meet stringent NPDES permit limits to discharge into the Blue River.

After treating the MWTP with PBII, the system established a better settling and more equipped biomass for processing influent waster. The facility now keeps PBII on hand to restart the plant instead of hauling activated sludge.

BioLynceus® ProBiotic Scrubber® II is an effective seed for restarting MWTPs.

1 Jenkins, D., Richard, M.G., Daigger, G.T., 2003. Manual on the Causes and Control of Activated Sludge Bulking, Foaming, and Other Solids Separation Problems. Lewis Publishers, Boca Raton, FL.

https://www.crcpress.com/Manual-on-the-Causes-and-Control-of-Activated-Sludge-Bulking-Foaming/Jenkins-Richard-Daigger/p/book/9781566706476

2 Krhutkova O, Ruzickova I, Wanner J. Microbial evaluation of activated sludge and filamentous population at eight Czech nutrient removal activated sludge plants during year 2000. Water Sci Technol 2002;46(1/2):471–8.

https://www.ncbi.nlm.nih.gov/pubmed/12216670

3 Palm JC, Jenkins D, Parker DS. Relationship between organic loading, dissolved oxygen concentration and sludge settleability in the completely mixed activated sludge process. J Water Pollut Control Fed 1980;52:2484–506.

https://www.jstor.org/stable/pdf/25040913.pdf?seq=1

Startup of a Fixed-Film Activated Sludge Process

Mechanical WWTP 1 MGD

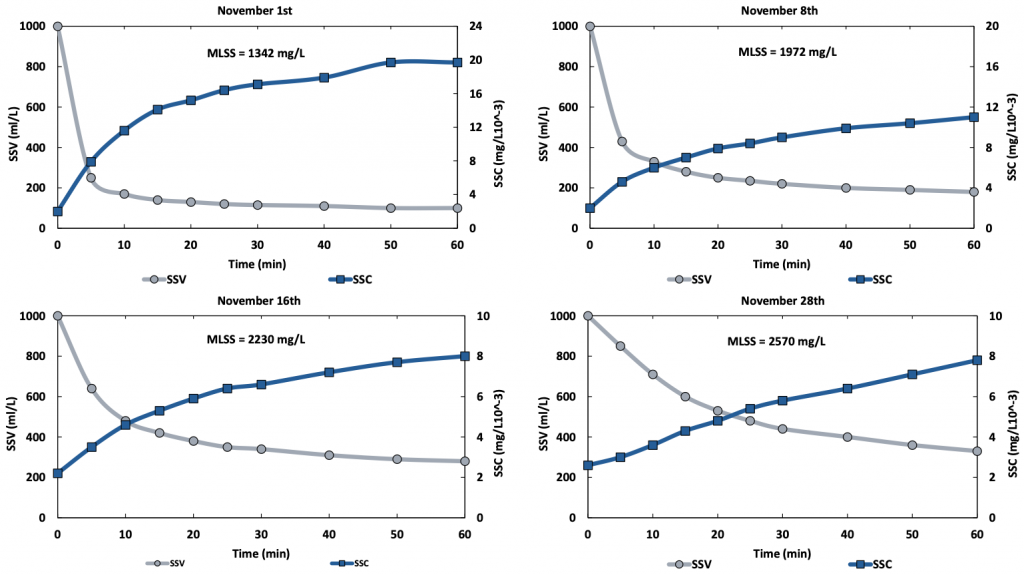

Establishing a functional biological community for wastewater treatment is essential when starting a new plant. Monitoring the growing biology during a startup provides the insight plant staff need to adjust operations to achieve a high treatment efficiency. Settleometer testing of aeration basin effluent in activated sludge processes can indicate whether the biomass will settle properly or cause bulking in the system.

From evaluation of settleometer readings and facility mixed liquor suspended solids (MLSS) concentrations, operators can calculate sludge volume index (SVI) values that describe biomass settleability. SVI values are variable in activated sludge systems, but Jenkins et al. (2003) found that sludge bulking occurs at SVI numbers greater than 150 ml/g.1 The following case study outlines the startup of a 1 MGD integrated fixed-film activated sludge (IFAS) process using ProBiotic Scrubber® II (PBII) as seed.

A wastewater treatment facility in Colorado, servicing 6,600 people, needed an upgrade of their current infrastructure. The original mechanical plant was built in 1956 and was last upgraded in 1985. In 25 years, the plant had deteriorated to the point where the effluent ammonia levels were exceeding permit limits.

This was an issue because their effluent was released to the Arkansas River, an essential water resource for downstream farmers and municipalities. To get the plant discharge back in compliance, the management of the facility decided to add on a new treatment train to the existing system. They added an IFAS process that had a higher treatment capacity than the old trickling filter plant.

After construction was completed, the system needed to be seeded with the proper biology for efficient wastewater treatment. The operators were hesitant to seed the new IFAS process with activated sludge from the old plant. They did not want to transmit the same treatment issues from the existing system to the new one.

Because of logistical concerns and expenses, the project engineer decided to use BioLynceus® PBII to startup the plant. The IFAS process was inoculated with PBII in the aeration basin under low flow conditions. After 10 days of treatment, the biomass in the new process had aggregated and was ready to start processing the full influent load.

Figure 1. Settled sludge volume (SSV (grey)), settled sludge concentration (SSC (blue)) determined from aeration basin effluent sampling throughout the first month of IFAS operations. SSVs of the wastewater samples were recorded over 60 minutes in a settleometer test. MLSS were acquired on settleometer testing days. SSC values were calculated using the SSVs and MLSS.

Settleometer testing was conducted throughout the first month of IFAS system operations. The results from the settleometer tests showed SSV decreased over time and SSC increased. These parameter trends indicated proper settling in the aeration basin effluent.

Additionally, SVI values were calculated from the 30-minute SSV for each settleometer test. The averaged SVI number in the first month of operations was 130 ml/g which was under the threshold for a poor settling biomass.

After adding PBII for a month, the operations reports showed that the clarifiers were fully functioning, and discharge was within NPDES limits. The PBII treatment provided the facility with an optimal biomass for wastewater processing. The system was working so efficiently, the plant was selected as wastewater system of the year in 2013 by the Colorado Rural Water Association.

BioLynceus® ProBiotic Scrubber® II is an effective biological seed for IFAS system startups.

1 Jenkins, D., Richard, M.G., Daigger, G.T., 2003. Manual on the Causes and Control of Activated Sludge Bulking, Foaming, and Other Solids Separation Problems. Lewis Publishers, Boca Raton, FL.

https://www.amazon.com/Control-Activated-Bulking-Separation-Problems/dp/1566706475