Mechanical WWTP .06 MGD

National parks attract millions of visitors each year. Increasing seasonal traffic experienced by these establishments can overload the wastewater treatment infrastructure leading to treatment inefficiency and, eventually, structural replacement.

When starting up a new plant, seeding with a healthy biomass is vital for instilling long-term treatment efficiency. The following case study outlines the startup of a membrane reactor (MBR) with Probiotic Scrubber® II (PBII) and small amounts of activated sludge.

Figure 1. Fully installed and operating Kubota MBR System. https:// www.kubota.com/products/solutions/

A national park in Wyoming was installing a new 0.06 MGD Kubota manufactured MBR system (Figure 1) to replace their old and overloaded conventional activated sludge (CAS) plant. The quantity of wastewater processed by the CAS plant continually increased each tourist season, May to October. The high flows generated by the transient populations at the park frequently overwhelmed the facility.

Specifically, during the summer, the mechanical plant received flows which well exceeded the small system’s treatment capacity. Because the volume of influent delivered to the CAS facility was beyond design specifications, the effluent quality was declining, and the facility operators were concerned with meeting their NPDES permit limits.

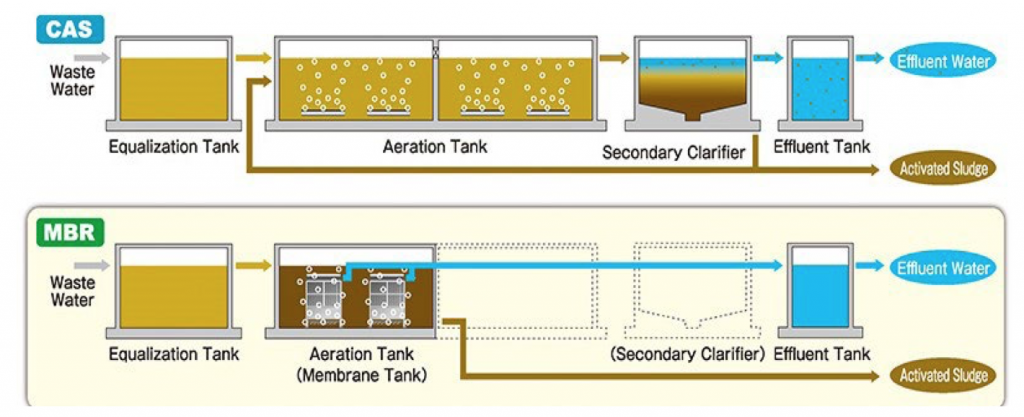

Figure 2. System diagrams comparing the treatment components of a CAS and MBR. The Kubota MBR does not require a secondary clarifier. MBR systems have greater treatment capacities with much smaller footprints. https://www.kubota.com/products/solutions/

The plant management decided their infrastructure needed to be replaced with a system which could handle higher flows (Figure 2). Designing and building the new MBR facility would take a minimum of two years. During that time, the current plant was required to meet permit limits.

The Utilities Supervisor at the Park contacted BioLynceus® to design a bioaugmentation plan to improve the biological treatment efficiency of their old system. The Park used PBII at their facility while the new MBR was constructed. PBII provided the biology needed to process high flows and keep the plant within permit compliance.

When the time came to startup the MBR facility, the management at the plant decided to use a combination of PBII and activated sludge to seed the reactor. Maintaining a high treatment efficiency was essential when starting up the new plant, so they opted to add PBII into the system from the beginning.

By adding BioLynceus® product, the plant reduced their sludge hauling costs, because they needed less activated sludge to start the reactor.

From startup, the MBR system was properly processing influent wastewater. Seeding the reactor with PBII was financially beneficial for the Park and helped to instill a biomass that promoted efficient treatment in their new system.

BioLynceus® ProBiotic Scrubber® II provides an effective biomass for MBR startup.