An effective activated sludge system has the capacity to remove ammonia from influent wastewater via nitrification.

Several factors impacting efficient ammonia and nitrite oxidation in wastewater treatment include, temperature, and abundance of carbonaceous and nitrogenous biological oxygen demand (cBOD & nBOD) degrading microorganisms.

The optimal temperature for wastewater nitrification is above 59°F.

Additionally, bacteria that quickly degrade cBOD help to increase the time available for nitrifying bacteria to oxidize ammonia and nitrite.

Nitrification is often the rate-limiting reaction in wastewater treatment, so having a high abundance of nitrifying organisms is essential for efficient ammonia and nitrite removal.

Augmenting a treatment system with concentrated populations of nitrifying and cBOD metabolizing biota can help improve nitrification.

BioLynceus® provides multiple products to assist with achieving objectives in the nitrification process.

The experience of four wastewater treatment plants, three activated sludge facilities and a lagoon system, is described in this paper.

Three different BioLynceus products were employed to improve nitrification.

Improving nitrification at a 0.2 MGD activated sludge facility

An Arizona activated sludge wastewater facility experienced excess ammonia in their effluent. Nitrification was not occurring properly causing them to risk violating their limit for total nitrogen. Restoring a nitrifying biomass was very important to avoid permit violations.

The facility had success using BioLynceus® products in the past, so the Operations Manager decided to use PBN to improve ammonia conversion in their system. Daily doses of PBN were administered to the lift station ahead of the primary treatment process.

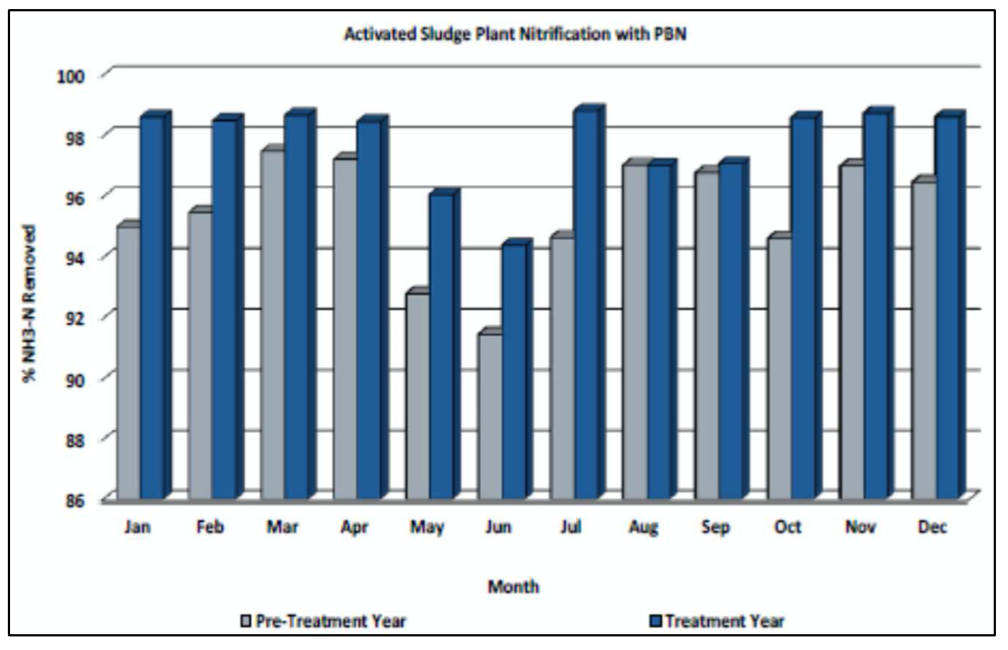

Within days, concentrations were lowered, and total nitrogen levels were comfortably below permit limits. Continual treatment with ProBiotic Scrubber® N (PBN) also improved ammonia removal by an annual average of 3% (Figure 1). The greatest ammonia removal increase was 4% in July, and the least was 0% in August. Using the BioLynceus® bioaugmentation program improved ammonia removal. The client continues to experience the efficacy of PBN for improving nitrification in their systems.

0.2 MGD Oregon activated sludge plant resolves high ammonia issues

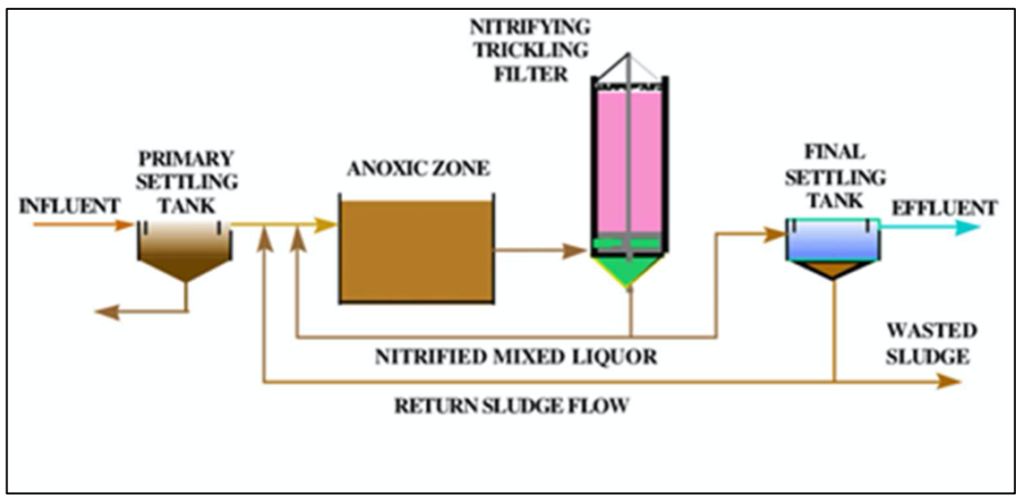

In Oregon, a wastewater treatment facility utilizes activated sludge treatment with fixed media trickling filters. They experienced high ammonia levels in the plant effluent. Nitrifying bacteria in the trickling filters were inhibited by undesirable wastewater quality conditions experienced during the summer months. Influent flows were low and varied in temperature and pH. Variability in the physical wastewater parameters impaired nitrification causing high effluent ammonia concentrations. The effluent quality was near exceeding the facility’s NPDES (National Pollution Discharge Elimination System) permit for ammonia.

BioLynceus designed a specialized bioaugmentation plan for the facility. ProBiotic Scrubber® N (PBN) was implemented between the anoxic zone and the plant trickling filters. PBN is a live culture product abundant in nitrifying bacteria and organic substrate degrading microbes.

After a few days of treatment, the biology in the system was properly nitrifying. Ammonia concentrations in the effluent decreased. BioLynceus® bioaugmentation with PBN helped the plant stay in compliance with their ammonia permit. The facility continued to use PBN from May to October to promote efficient nitrification in their trickling filters.

Establishing an effective community of nitrifying bacteria in wastewater treatment systems can be challenging. This process is most efficient in the correct environmental conditions. Temperature extremes and variable pH decrease process efficiency. Beyond the physical factors impacting nitrification in wastewater processes, maintaining a high abundance of nitrifying and organic matter degrading organisms is essential for optimal ammonia conversion. Nitrification is often the rate limiting reaction in wastewater treatment. This process has low energetic yield for nitrifying bacteria which impacts growth rates and abundance. Because of this, these bacteria require a high residence time in the aerobic process to oxidize ammonia properly. Bioaugmentation, like the treatment used in the example described above, can be a helpful solution to improve nitrification in activated sludge treatment processes.

Nitrification Improved at an Aerated Lagoon System with BioLynceus® ProBiotic Scrubber® II

Municipal lagoon systems are often challenged with facilitating nitrification. Nitrifying bacteria are responsible for removing ammonia from wastewater. These organisms are generally in low abundance in lagoon processes. Nitrification is an energetically taxing process and nitrification is easily disrupted by variation in physical parameters in the wastewater. For example, moderate alkalinity and temperature changes can impair ammonia oxidation. There is limited control over the physical conditions in lagoon systems. Because of these margins, nitrification is often the rate- limiting reaction in a lagoon treatment process.

Lagoon systems can be augmented with concentrated cultures of nitrifying bacteria to promote nitrification. Bioaugmentation with BioLynceus® ProBiotic Scrubber® II (PBII) can be beneficial to a lagoon system struggling to remove ammonia.

A 0.2 MGD covered lagoon system in Colorado was having issues maintaining a nitrifying biomass. At times, the process basins had inconsistent temperature and low alkalinity. During the winter months the wastewater would become very cold halting nitrification. Alkalinity was not well maintained in the system. These factors, among others not identified, limited effective nitrification in the lagoons. The utility needed to improve ammonia removal to meet discharge permit limits.

They contacted BioLynceus for assistance. A treatment plan with BioLynceus® ProBiotic Scrubber® II (PBII) was suggested by BioLynceus. PBII is a highly diversified consortium of living bacteria abundant in nitrifiers.

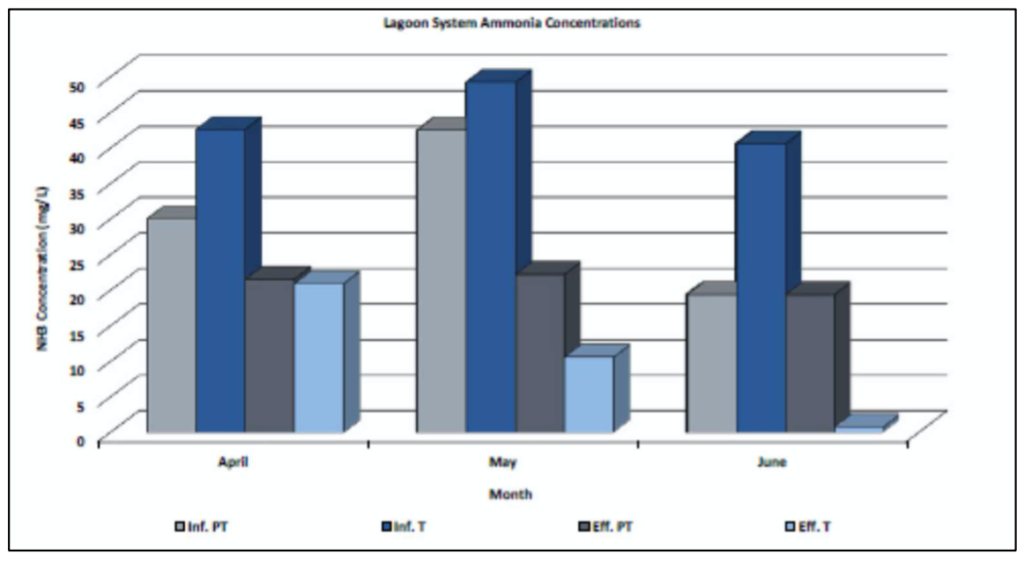

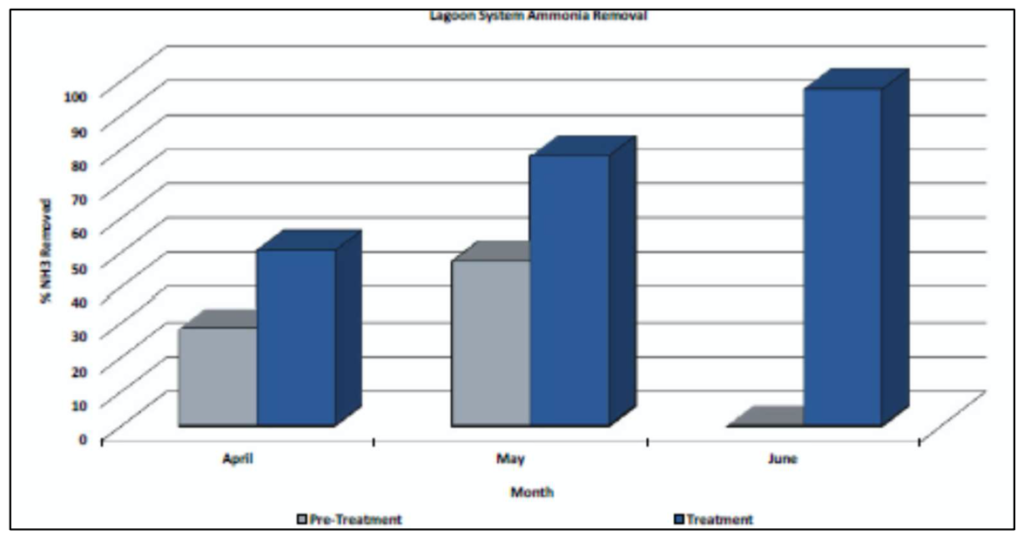

PBII was added in the lagoon to stimulate the nitrification process. PBII was applied over three months, April, May and June. Wastewater temperatures were above 3°C. Compared to the same time period the previous year, influent ammonia concentrations increased each month, and effluent concentrations decreased (Figure 3).

PT & Inf. T) and effluent (Eff. PT & Eff. T) ammonia concentrations are displayed as measured in the lagoon system for two consecutive years in April, May, and June.

Effluent ammonia concentrations were approximately 96% lower following treatment withPBII. Furthermore, percent ammonia removed in the process was increased by 23% in April, 31% in May, and 98% in June (Figure 4).

Augmenting the lagoon system with PBII supported efficient nitrification and resulted in better effluent quality. The utility continued to meet their discharge permit limits.

4.5 MGD Aerobic Wastewater Treatment Facility Recovers from Loss of Nitrification

Located in northern Colorado, the 4.5 MGD capacity aerobic treatment facility serves a suburban population of about 45,000, the influent stream is primarily domestic sewage with some waste from commercial and industrial facilities. Limiting nutrients in the plant effluent is important. The effluent enters an irrigation reservoir and is also a public recreation area. Discharge from the reservoir is used for agriculture and ultimately enters the South Platte river.

During the spring of 2020, with influent flows averaging 3.4 MGD, the facility experienced a loss of nitrification. This, of course, adversely affected the nutrient loading being discharged. ProBiotic Scrubber® NN (PBNN) from BioLynceus was used to recover and return to normal operation.

ProBiotic Scrubber NN® provides an environment designed to help reduce the impact of nutrient loading in wastewater streams. ProBiotic Scrubber NN® is a natural liquid bioaugmentation formulation designed to increase decomposition of organic and inorganic materials. ProBiotic Scrubber NN® is a diverse consortium of beneficial bacteria with a high concentration of nitrifiers.

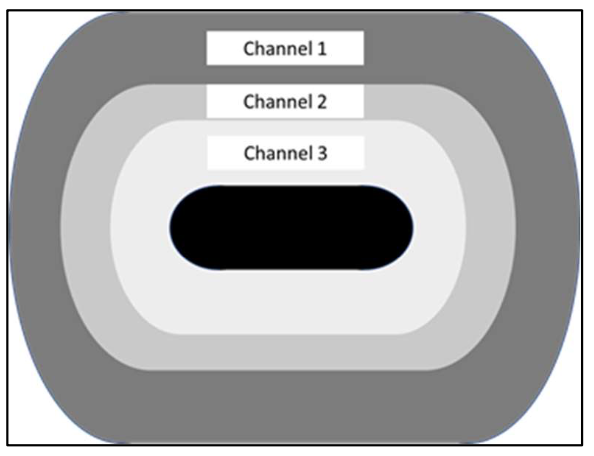

The facility uses an Evoqua Orbal® oxidation ditch. The Orbal system uses an activated sludge process designed to achieve simultaneous nitrification/denitrification (SND) The system features three concentric rings (channels 1, 2 and 3) to establish dedicated zones for specific treatment purposes. These treatment zones operate in series during the SND treatment process.

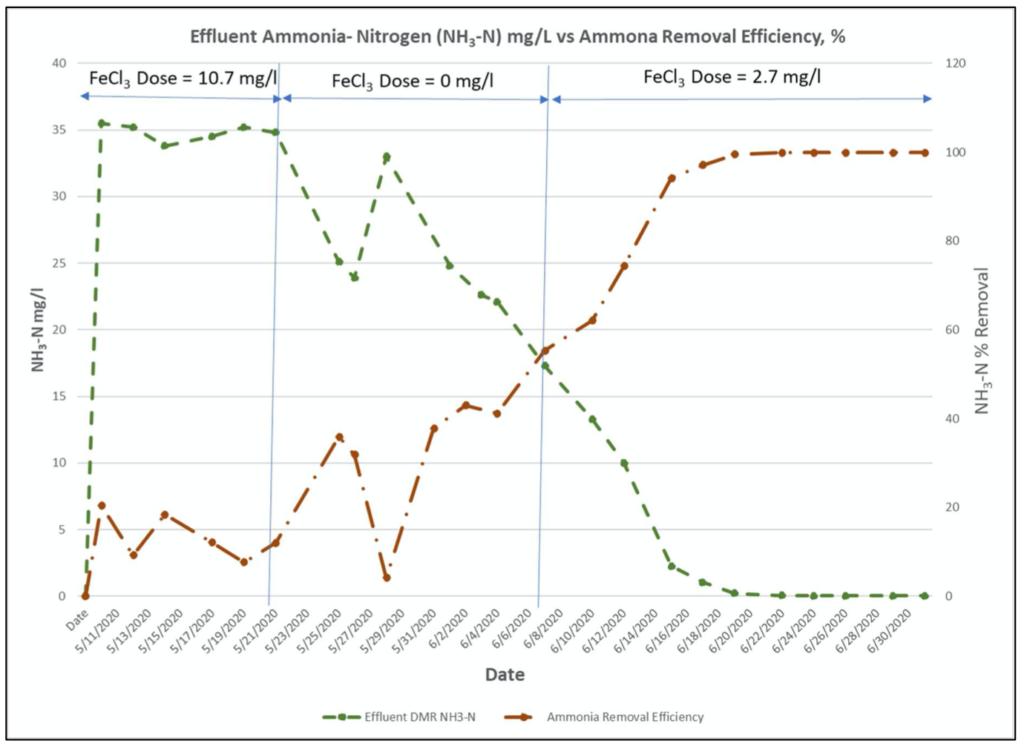

Hydrogen sulfide (H2S) is problematic at one of their lift stations. Ferric chlorine, FeCl3, is added to treat the H2S problem. The chart (Figure 5) illustrates from May 11-21 FeCl3 was fed at a rate of 300 #/day at the lift station. Ferric feed was stopped on May 21 and then restarted at a rate of 75#/da from June 6-30. The influent plant flow averaged 3.4 MGD during this time period. Thus, the ferric dose in the plant influent amounted to 10.7 mg/l for May11-21 and 2.7 mg/l for the period of June 6-30. This is important because FeCl3 consumes (reacts with) 0.93 mg/l of bicarbonate (HCO3-) alkalinity as CaCO3 per mg/l of FeCl3. The ferric doses lowered the influent alkalinity approximately 10 mg/l from May 11-21 and 2.5 mg/l from June 6-21.

By comparison, the nitrification process is generally considered to require7.14 mg/l bicarbonate alkalinity per mg/l NH3-N removed. Figure 5 indicates over the course of the study nitrification improvement resulted in reduction of about 30 mg/l NH3-N. This reaction will require (consume) approximately 214 mg/l alkalinity.

Alkalinity of wastewater varies based on the source water for the system, e.g. surface water or ground water. It is not uncommon for wastewater influent alkalinity to range around 215-240 mg/l. The nitrification process must include monitoring of alkalinity and, if necessary, to provide an addition source of alkalinity.

One can see also that while the ferric dose in this case consumed only about 5% of the amount required for nitrification, in low alkalinity influent streams it could have a significant impact. Systems should be diligent in accounting for all the steps in the treatment process that may impact available alkalinity.

One of the benefits of the Orbal design is denitrification in the same system. Denitrification produces bicarbonate alkalinity at the rate of 3.57 grams per gram of NO3-N converted to N2 gas. So, if the treatment system achieves denitrification, some of the alkalinity consumed during nitrification is regained.

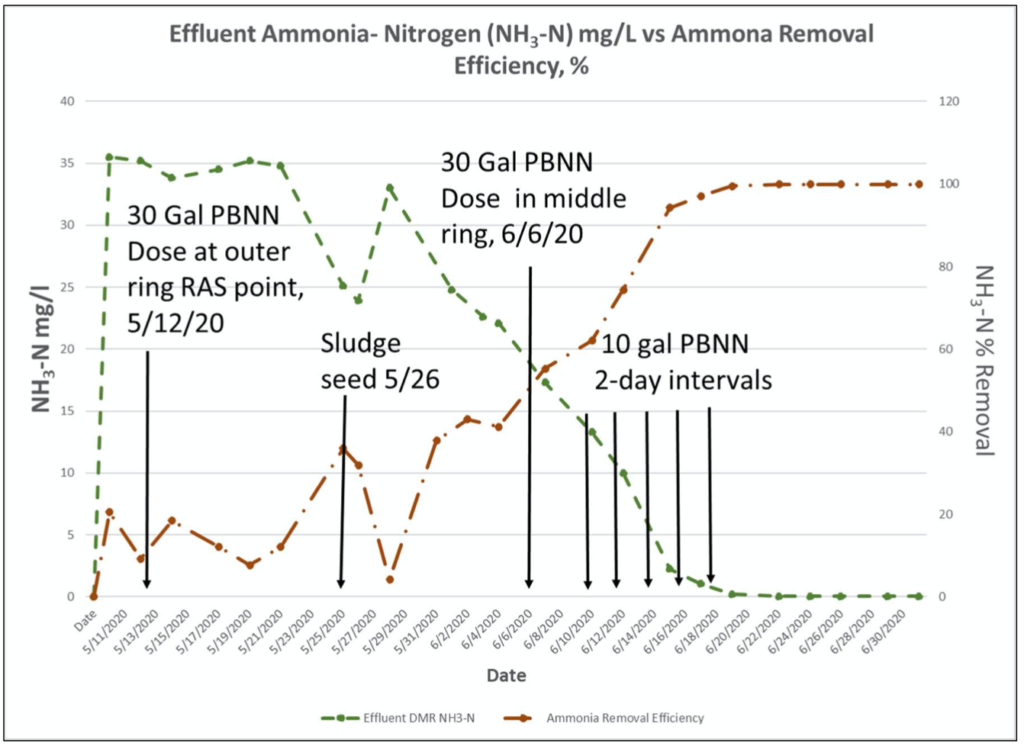

In early May of 2020, the treatment plant lost their nitrification. ProBiotic Scrubber NN® (PBNN) was used in an attempt to reestablish nitrification. On May 12, 30 gallons of PBNN were added to the outer ring, Channel 1 near the point of RAS (return activated sludge) addition. This zone is typically anoxic. Because of this, the addition of PBNN was ineffective.

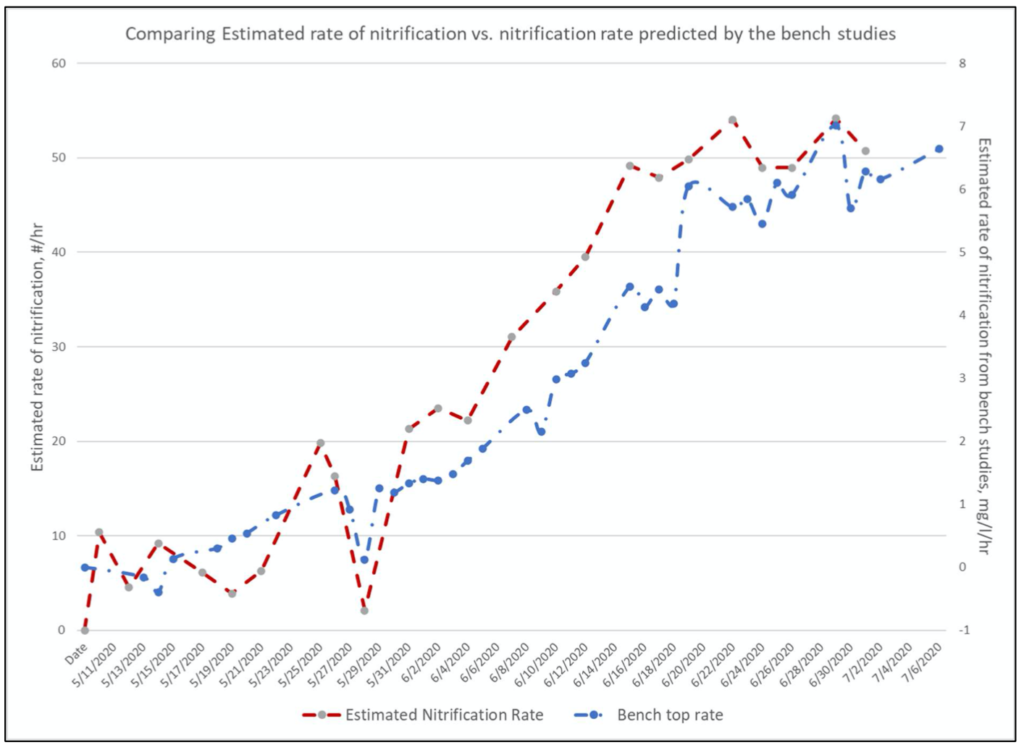

The plant staff used a 2-liter settleometer for an innovative bench top reactor to try to simulate the problem. The influent alkalinity and effluent alkalinity were monitored to ensure there was sufficient alkalinity in the system. Figure 8 illustrates how the estimated rate of nitrification compared to the values obtained in the bench studies. The trends are very similar.

It was decided to try to add activated sludge from a neighboring facility to reseed the process. Bleach was applied and wasting was increased to prepare for the seed. On May 26 36,000 gallons of the seed sludge was added. Some improvement was achieved – a decrease from about 25 to 20 mg/L NH3-N between May 26 and June 4.

Plant personnel asked BioLynceus for assistance. BioLynceus suggested a multiple step feed protocol where PBNN would be added over a 12-day period to the middle ring, Channel 2. Channel 2 in an Orbal system typically maintains about 1 mg/l DO. An initial quantity of 30 gallons of PBNN was to be added. Then, two days later an additional 20 gallons. Six more doses of 10 gallons each were to follow at 2-day intervals. The new treatment started on June 6 with 30 gallons, June 8, 20 gallons. Ten gallons were added each day on June 10, 12, 14, 16 and June 18. See Figure 9.

On June 4 the effluent NH3-N as 22.1 mg/l. By June 12 the effluent value dropped to 10 mg/L. By June 15 the value dropped to 2.26 mg/l NH3-N. Improvement continued. By late June the NH3-N values were consistently less than 0.08 mg/L.

Using PBNN, the prescribed treatment regimen, and diligence of the utility staff resulted in successfully restoring nitrification.

BioLynceus offers solutions to treatment challenges

BioLynceus has a number of products to address treatment issues and objectives. We work with our customers to select the proper product and to find the proper application technique. One can see in the studies summarized above Probiotic Scrubber II, Probiotic Scrubber N and Probiotic Scrubber NN were used effectively to establish improvements to the nitrification processes.

Four applications with three different products used to provide solutions to a nitrification issue.

One size doesn’t fit all – Let BioLynceus provide assistance in finding a solution to fit your treatment challenges.

ProBiotic Scrubber® II is a registered trademark of BioLynceus® LLC ProBiotic Scrubber® N is a registered trademark of BioLynceus® LLC ProBiotic Scrubber® NN is a registered trademark of BioLynceus® LLC BioLynceus® is a registered trademark of BioLynceus® LLC ©Copyright August, 2020 by BioLynceus® LLC, All rights are reserved

[/et_bloom_locked]