When starting up a wastewater plant, the biological seed used can influence future treatment efficiency and operational challenges. Domestic activated sludge or digester sludge seeding has potential to introduce unwanted biological and solids contaminants that can cause unpredictable treatment issues.

Whether the source plant was experiencing any problems or not, varied plant conditions can shift microbial community dynamics to impair treatment efficiency. In addition to biomass instability, activated sludge or digester sludge used as seed can introduce large trash particulates and inorganic solids requiring mechanical removal.

Wastewater facilities seeking a clean, controlled startup can benefit from using bioaugmentation for plant seeding. Augmenting a system with intentionally cultured communities of wastewater bacteria can help eliminate uncontrolled treatment challenges that often follow inoculation with sludge from a domestic wastewater treatment process.

Membrane bioreactor (MBR) plant startup at a cider mill

A cider mill in Pennsylvania is in production from August to November each year. During this time, the MBR on site treats 0.01 MGD wastewater flows from the manufacturing process. After the production season is over, the wastewater plant is drained and cleaned in preparation for the next year. Thus, the plant requires startup every summer when cider manufacturing begins again.

The MBR was usually started with activated sludge form a neighboring municipal plant. Startups with domestic activated sludge caused operational challenges for the facility because the sludge introduced rags and trash into the system. The unwanted domestic debris impaired flow through the MBR.

In need of a cleaner and more reliable seed, the wastewater management contacted BioLynceus®. Probiotic Scrubber®II (PBII) was inoculated at the influent to the plant to start biological processing in the MBR. This seed introduced live cultures of diverse wastewater bacteria to the system.

Within two weeks of treatment, the cider mill wastewater plant was efficiently processing influent flows. The effluent from the plant was in compliance with publicly owned treatment works permitting. Furthermore, the operations staff no longer needed to remove trash for the process to work efficiently.

Seeding the MBR with domestic activated sludge limited the manufacturer’s wastewater reuse – effluent was effectively wasted. Using PBII for startup seed made it possible for the cider mill to use the treated wastewater to irrigate their apple orchards.

BioLynceus® cultures provided a clean startup method with less operational challenges than previous activated sludge seedings. And, the cider mill was able to make more beneficial use of its water resources.

Anaerobic digester startup at a sugar refinery

Processing sugar beets is characterized as a campaign for good reason. From the beginning of harvest in late summer or early fall to the time the last beet is processed in early spring it is a campaign – 7-day per week, 24-hours per day. All of the parts of the process are vital to maximizing the yield and profitability:

harvest –> managing the stock piles –> processing the beets –> handing the waste

The process generates a large amount of waste that must be properly treated. Difficulties in managing the waste stream can have a significant impact on operating costs and therefore profitability.

Halfway through a sugar beet processing campaign (September through May) a waste treatment engineer at a midwestern sugar refinery noticed something was wrong with their wastewater processing system.

The plant discharge was within limits for their NPDES permit parameters, but the chemical oxygen demand (COD) readings from their 8.9-million-gallon anaerobic digester were very different at the top, center, and bottom of the digester. The system engineer suspected the mixers were not operating properly.

Without functional mixing, the digester was unable to process the high COD wastewater from the sugar refinery efficiently. Since they continued to be within limits for their discharge permit, repair to the digester’s mixing blades was deferred to the end of the campaign.

The anaerobic digester was emptied and cleaned thereby removing all active biology in the tank. The newly cleaned and repaired anaerobic digester needed to be reseeded to reestablish a healthy biota to return to effectively processing high COD wastewater.

The initial plan was to use sludge from a neighboring sugar refinery’s anaerobic digester to seed the repaired digester. This process would involve hauling thousands of gallons of sludge, an expense ranging between $70,000 and $100,000.

In addition to cost, seeding with sludge from another facility can be highly time consuming and risky. The hauled sludge can introduce unknown foreign contaminates to the newly cleaned and repaired system. This potential contamination can cause unpredictable treatment issues in the future.

The plant waste managers sought alternative options, which lead them to BioLynceus®. The team at BioLynceus® suggested reseeding with Probiotic Scrubber® II (PBII). This live culture treatment would supply the digester with a diverse microbial community and give the company a more cost- effective and more reliable solution. And, the cost of hauling digester sludge was eliminated.

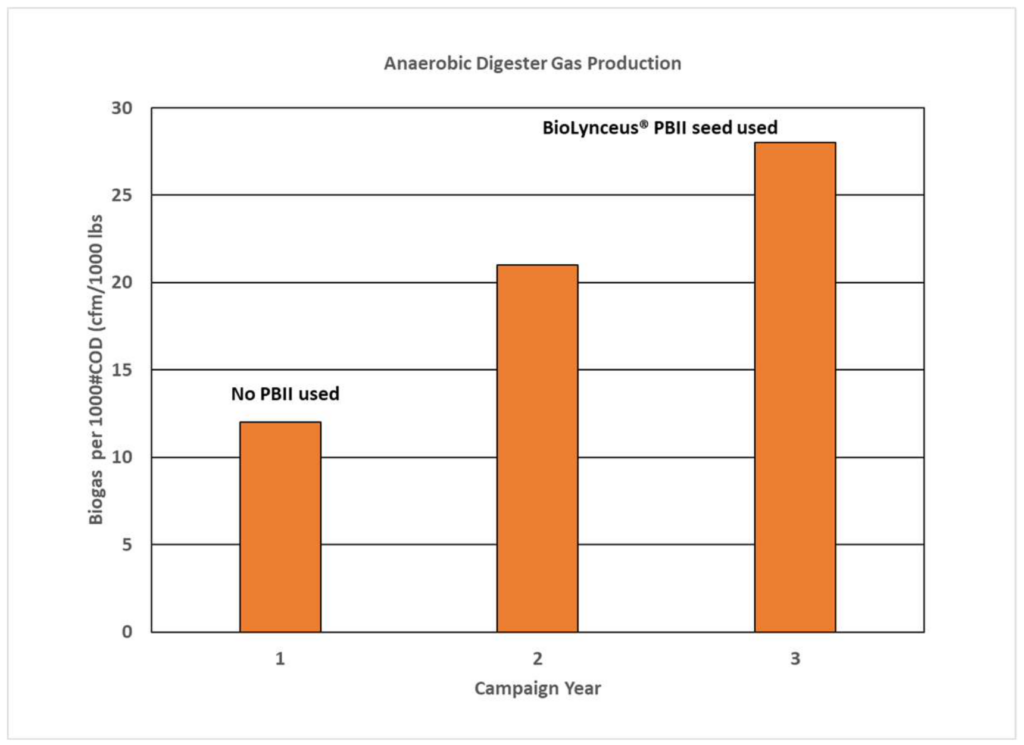

PBII was added to the digester along with the facility’s high strength COD wastewater to restart the digester. After four days of implementing PBII, consistent methane was being produced by the digester; indicating the microbiology was properly processing the influent COD. Seeding the digester with PBII saved the refinery time and money.

An additional benefit of treating with PBII was the quantity of methane produced was much higher than before treatment. The average increase in biogas produced during the second and third campaign was 13 cfs per 1000 lbs. COD. Cleaning out the digester and repairing the mixers before implementing PBII also contributed to improving methane production. The methane produced is used as a fuel source to help operate the drying kilns.

With BioLynceus®, the anaerobic digester was started with less financial burden than using sludge, and the biogas produced from the digester provides the refinery with a stable energy source and lower costs than purchased natural gas for the kilns.

Seeding with activated sludge may create problems with filamentous bacteria

Choosing an appropriate seed method for wastewater operations can have a significant impact on biological treatment efficiency. Activated sludge is commonly used to seed new or re-started aerobic treatment systems and supplement others that need bioaugmentation. A frequent issue in activated sludge systems is sludge bulking – the uncontrolled growth of filamentous bacteria1.

Nocardia and Microtia parvicella are two organisms often identified when bulking occurs. The variety of filamentous bacteria can vary based on the cause of the bulking. Impacts of a bulking sludge include (but are not limited to) poor settleability, impaired biological nutrient removal, and increased facility maintenance.

It is difficult to predict whether sludge bulking will occur in a newly seeded wastewater process. Filamentous bacteria in activated sludge respond differently to varying system conditions. One method to prevent bulking is to quantify the proportion of filamentous bacteria in activated sludge before inoculation. Previous studies have found that sludge bulking can occur in systems with a volume fraction of filamentous bacteria as low as 1-20%.2,3

Even when filament forming organisms are in low abundance, they can still cause treatment issues. Bioaugmentation with a specifically designed microbial community can be a more reliable alternative to using activated sludge as seed.

The following case study outlines the use of ProBiotic Scrubber® II (PBII) in a 0.7 MGD mechanical wastewater treatment plant (MWTP) to restore a healthy biomass after the plant was reseeded with activated sludge containing high amounts of filamentous bacteria.

Startup Mechanical Plant After Failed Activated Sludge Seeding of an RBC

The wastewater from a small resort town in Colorado was processed at a mechanical plant with rotating bed contactors, aka rotating biological contactors (RBC), for nutrient removal and gravity filtration for tertiary treatment.

The plant was operating properly until a concentrated load of petroleum based toxic waste was introduced to the system. The biomass was severely damaged by this event. Reseeding was necessary to reestablish the healthy biomass. The operators added several loads of activated sludge from a neighboring wastewater treatment facility to reseed the plant. Troublebeganquickly!

Shortly after inoculation, the operators began to have difficulty with foaming, settleability, and continuously clogged filters. Operators were scheduled around the clock just to keep up with backwashing the tertiaryfilters. After examining a mixed liquor sample from the plant, the head operator realized that filamentous bacteria were thriving in the reactor and were preventing solids and nutrient reduction from occurring.

They needed to decrease the abundance of these organisms to resume proper wastewater processing. The facility management contacted BioLynceus® to provide a bioaugmentation plan to reinstate a healthy biological population.

BioLynceus® PBII was supplied to the aeration tank of the 0.7 MGD system. 24 hours after PBII was applied, nitrification was restored in the basin. Suspended solids were gradually reduced in the plant effluent over several weeks.

This indicated that the biology in the facility was shifting to a more desirable composition; one that was allowing settling to occur. Foaming was also reduced in the aeration basin. The operators were relieved to see such an improvement in their biological treatment, because they had to meet stringent NPDES permit limits to discharge into the Blue River.

After treating the MWTP with PBII, the system established a better settling and a healthier biomass for processing influent wastewater. The facility now keeps PBII on hand to restart the plant instead of hauling activated sludge.

Study Demonstrates Effectiveness of PBII to Boost Methane Production

Utilizing methane gas from anaerobic digesters (AD) provides energy savings and reduces wastewater industry greenhouse gas impacts. Methane is an inevitable by-product of anaerobic digestion. It is beneficial, when possible, to capture and use the methane.

When methane is converted to carbon dioxide (CO2) and water vapor during combustion, the global warming potential of the CO2 emitted decreases by a factor of 23 4. As the benefits of methane production becomes more recognized in the wastewater treatment field, the prospect of maximizing this energy source through biological optimization gains greater attention.

In early 2019 SUEZ Water Technologies and Solutions5 began a study of BioLynceus® Probiotic Scrubber®II (PBII) to test its effectiveness in increasing anaerobic digester methane production. PBII contains highly concentrated live cultures of microbiology that is used to optimize wastewater treatment plants.

The study was conducted at their research facility in Oakville, Ontario, Canada. The serum bottle method was used. The study compared the biochemical methane potential (BMP) of PBII against sludge from a highly monitored research digester (SOWC).

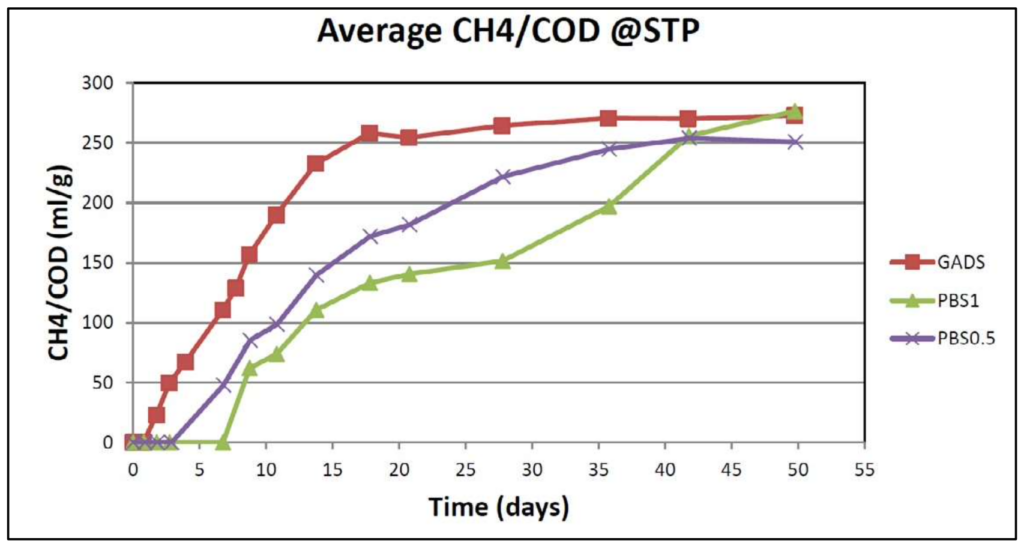

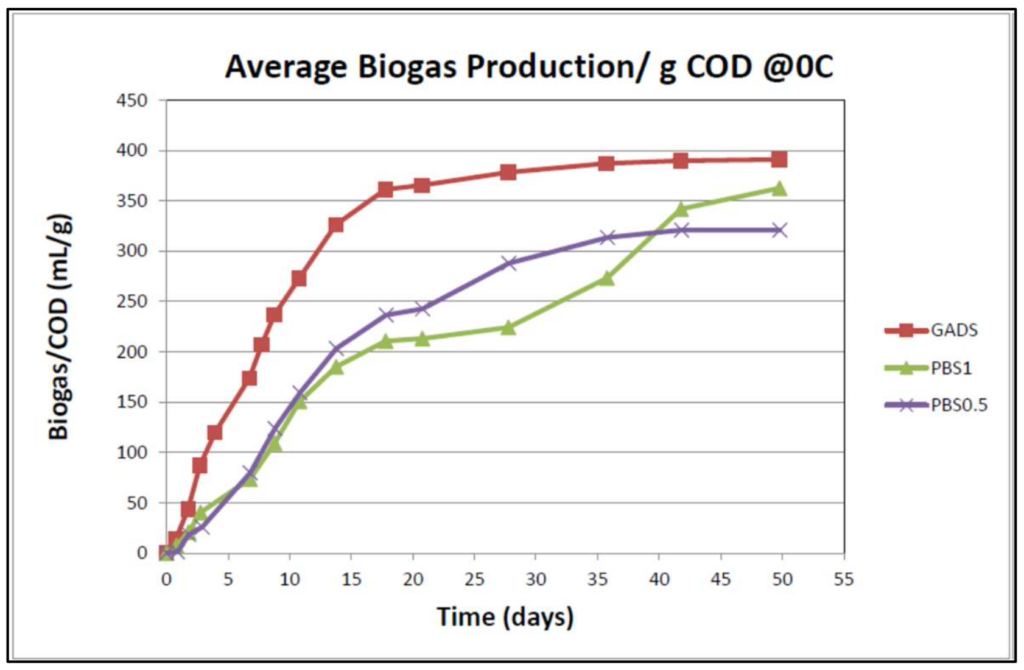

“The Probiotic Scrubber II (PBS) product was tested against AD sludge collected from the SOWC pilot at Guelph. The BMP test was performed to test both the sludge and the PBS product with an F/M ratio of 1. A second test condition was also performed for the PBS product where half the amount of seed was used, and the F/M ratio was doubled to 2.”6

To test the BMP of these substances as digester seeds, the serum bottle method was employed with triplicate samples for each seed source. The test bottles contained high strength brewery wastewater inoculated with three different treatments, anaerobic digester sludge (GADS) with a food to microbe ratio (F:M) of one, PBII (PBS1) with a F:M of one, and PBII (PBS0.5) with a F:M of two.

The volume of seed added to each bottle was determined by the proportions above, and the total volume encompassing the seed, wastewater, and 5-mL nutrient solution equaled 90-mL. A blank containing the corresponding treatment seed without the addition of wastewater was prepared for each bottle. The bottles were incubated for 50 days.

During the incubation period, the methane yield at standard temperature and pressure (STP) and total biogas yield at STP were monitored. The biogas and methane yield from the test bottles were corrected by subtracting the gas production of each complementary test blank.

On day 50, the average methane yield from the PBS1 treatment was 3.6 mg/g COD greater than from the GADS treatment (Figure 8). The PBS0.5 treatment produced the smallest 50-day average methane yield in the study which was expected considering the concentrations of biomass in the bottles were reduced by half. Using PBS1 as digester seed promoted increased methane production at the end of the BMP test when compared to the research sludge.

The total biogas yield on day 50 was greatest from the GADS bottles. Because the sludge produced more biogas and less methane than the PBS1 treatment, the study exhibited that the sludge off gassed higher quantities of carbon dioxide and other trace gases than PBS1.

The PBS0.5 bottles produced the least amount of biogas in the study. Using BioLynceus®’ product as seed optimized methane availability and minimized the formation of gases unsuitable for energy production. The testing report provided by the Anaerobic Technology Laboratory explained, “The [PBII] product performed well versus the AD sludge [GADS] as the seed in the BMP bottles.” 7

Overall, the results of the BMP test showed that PBII promoted more efficient methane formation by the end of the study than did the seeding method with digester sludge.

Augmenting a system with intentionally cultured communities of wastewater bacteria can help eliminate uncontrolled treatment challenges that often follow inoculation with sludge from a domestic wastewater treatment process. Probiotic Scrubber II has been shown to provide beneficial results in starting up a variety of processes, including an MBR, activated sludge and anaerobic digesters.

Call BioLynceus to find out how bioaugmentation can help solve your plant start up challenges.

BioLynceus® and ProBiotic Scrubber® are registered trademarks of BioLynceus® LLC ©Copyright February 2021 by BioLynceus® LLC, all rights are reserved.

References

1 Jenkins,D.,Richard,M.G.,Daigger,G.T.,2003.Manual on the Causes and Control of Activated Sludge Bulking, Foaming, and Other Solids Separation Problems. Lewis Publishers, Boca Raton, FL.

2 Krhutkova O, Ruzickova I, Wanner J. Microbial evaluation of activated sludge and filamentous population at eight Czech nutrient removal activated sludge plants during year 2000. Water Sci Technol 2002;46(1/2):471–8.

3 Palm JC, Jenkins D, Parker DS. Relationship between organic loading, dissolved oxygen concentration and sludge settleability in the completely mixed activated sludge process. J Water Pollut Control Fed 1980;52:2484–506.

4 Intergovernmental Panel on Climate Change (008), Cambridge University Press, http://www.ipcc.ch

5 An affiliate of SUEZ, an international conglomerate providing operations and consulting for water and wastewater treatment; and, solid waste handling. SUEZ has a global presence in these fields.

6 From the Suez Environmental BMP Test Study final report.

7 Biochemical Methane Potential Testing Report (2019). Suez GPD, Anaerobic Technology Laboratory. Pp. 2, 5.