Small municipal and industrial wastewater systems may find a lagoon system, in conjunction with a mechanical plant or as the only treatment, a cost-effective means of treating the waste stream. This paper addresses applications where a lagoon is the only means of treatment; reduction of FOG in a collection system prior to a mechanical plant; and, meeting compliance limits at a petroleum refinery.

Aerobic Lagoons

Aerobic lagoons may have air supplied via an integral aeration system using blowers somewhat akin to an activated sludge system. Thefourpondsystempictured at right comprises a total of approximately three surface acres. The flow is in series. One can observe the aeration can be varied in each of the four ponds such that the ponds can be operated in a variety of modes, aerated, anoxic or nearly anaerobic depending on the treatment objective.

Compare that to the much simpler pond system with a surface aerator pictured below.

Aerobic lagoons are typically well mixed thus having a uniform biota, chemical and biochemical content and similar physical characteristics, e.g. temperature and pH, from the surface to the bottom or sludge layer of the pond. They do not stratify as is possible for facultative lagoons.

Facultative Lagoons

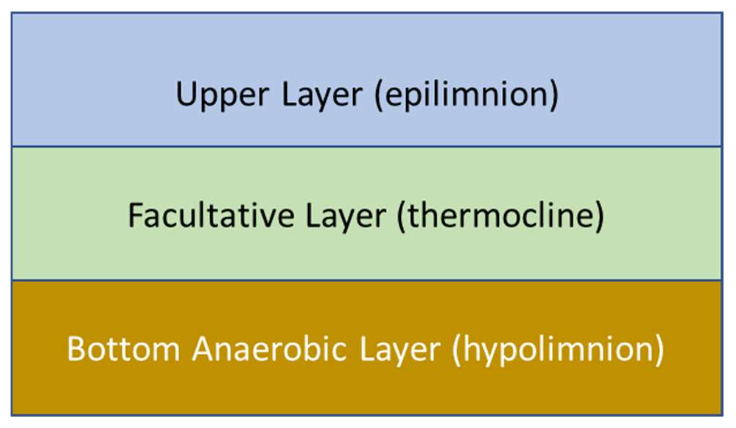

Facultative lagoon systems do not have supplied air. They can become stratified such that aerobic organisms predominate in water close to the surface with sunlight and atmospheric oxygen exchange. A variety of organisms including aerobic bacteria, algae and insects can thrive and contribute to breaking down the organic load (BOD and/or COD). The bottom of the pond will lack adequate sunlight and will typically be anoxic, often becoming anaerobic. Thus, an entirely different population of organisms work to continue breaking down the organic substances.

“The oxygen, produced by algae and surface reaeration, is used by aerobic and facultative bacteria to stabilize organic material in the upper layer of water. Anaerobic fermentation is the dominant activity in the bottom layer in the lagoon.”1

Stratification, Destratification and Turn Over

Bodies of water may become thermally stratified. The phenomenon can occur in bodies of water from small ponds, including facultative lagoons to very large lakes. The stratification is a consequence of the rather peculiar property of water – it has maximum density at 4°C (39.2°F). At temperatures above and below 4° C the water is less dense. For most reservoirs, stratification begins in early spring as the surface water warms faster than the rest of the reservoir – thus becoming less dense. The lower density, warm surface layer ‘floats’ on the more dense, cooler water in lower regions of the water body. The upper layer is termed the epilimnion. The lower layer is termed the hypolimnion. With time a third, transitional layer forms, the thermocline.

Some sources define a thermocline as a region where the temperature change is 1°C per meter of depth (about 0.55°F per foot). While the phenomenon in facultative lagoons is the same, the terminology is different.

As a change of season approaches (fall or spring) the facultative layer shrinks and disappears leaving only the top and bottom layers: “These layers may persist for long periods due to temperature-induced water density variations. Inversions can occur in the spring and fall when the surface water layer may have a higher density than lower layers due to temperature fluctuations. This higher density water sinks during these unstable periods, creates turbidity, and produces objectionable odors.”2

Study of behavior of layers is often overlooked by operators of facultative lagoon systems. Yet it can be quite important to proactively anticipating the impending change and being ready to adjust operation practices if needed.

Solids Management – Meeting the challenge

Whether aerobic or facultative the central purpose of a lagoon is to stabilize – reduce to simpler substances – the organic matter so that effluent from the lagoon does not create undesirable nutrient loading in the receiving stream. Sludge resulting from the process will accumulate in the bottom of the lagoon and need to be periodically removed with mechanical dredging. It stands to reason the more effective the treatment is, more of the organic load will become simply water, and carbon dioxide leaving little solid matter.

Conversely if the biological treatment is not effective, solids will accumulate more quickly. One of the most persistent challenges in management of wastewater lagoons is dealing with solids (sludge). Excess sludge accumulation decreases the volume of the lagoon available for treatment thereby reducing the treatment capacity of the system.

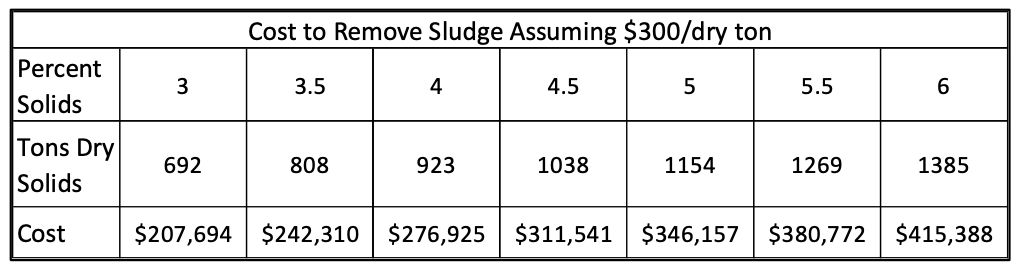

Sludge built-up is typically mechanically dredged from lagoon systems with heavy equipment. Once removed, sludge is dewatered and hauled to a disposal site. This process can cost $300 to $800 dollars per dry ton of solids. The following figure illustrates how cost will vary based on how the solids convert to dry tons. Sludge with a higher percentage of solids will result in more dry tons to be hauled.

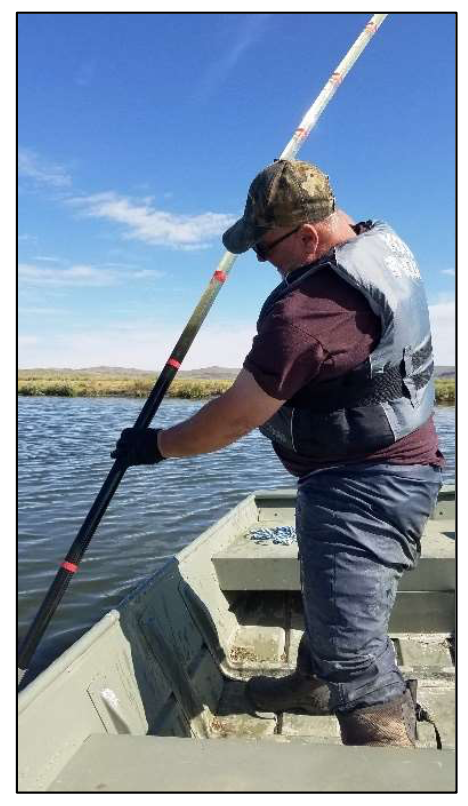

typically carried out using a sampling device, typically a

Sludge Judge®3 . A flat bottom boat is preferred as it

provides better stability. Photo Courtesy Mark Court, Registered Wastewater Technician, from the Wyoming Association of Rural Water Systems4.

A minimum of six sample points is typically suggested or for larger ponds, 6 points per acre. So, nine points would be suggested for a 1.5-acre pond. Multiple measurements are necessary as the sludge surface likely will not be uniform with some areas deeper than others. Once measurements are collected, then they can be averaged together.

Probiotic Dredging® in Municipal Wastewater Treatment Lagoons

BioLynceus Probiotic Scrubber® II (PBII) effectively reduces solids build up in municipal lagoon systems. By implementing concentrated cultures of bacteria (from natural soils and sediments) in these processes, treatment biomass is increased which can improve the efficiency of solids degradation. 5

Bioaugmentation is an effective method for reducing sludge in lagoon systems. This process is also called Probiotic Dredging®. Probiotic Dredging® gives the biota an opportunity to efficiently reduce sludge volume. Mechanical dredging will eventually have to be done to all lagoons but the money spent will be to remove well stabilized solids which are much more friendly to the environment.

The following examples highlight the effectiveness of PBII in municipal lagoons.

Significant Sludge Reduction in a 0.3 MGD Lagoon System

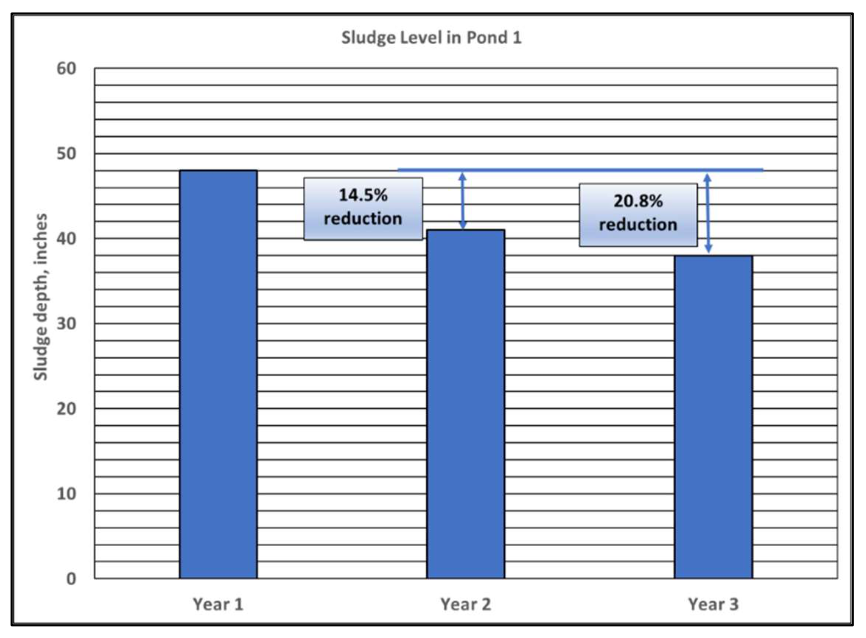

A publicly owned treatment works (POTW) in a community of 2,700 people was experiencing undesirable sludge accumulation in their aerobic lagoon system. The three treatment cells averaged 0.3 MGD wastewater flows (with some seasonal variability). The three ponds, each five feet deep, were accumulating too much sludge especially the first pond. It appeared mechanical dredging might be necessary – and expensive. The head wastewater operator learned about Probiotic Dredging® at a wastewater training conference.

lagoon system. Photo courtesy of Mark Sembach

The operator proposed Probiotic Dredging® to the city council. The council agreed to augment their system with BioLynceus® PBII. If successful, the council anticipated a significant reduction in mechanical dredging costs.

A treatment regimen of PBII was added to several high points in the collection system ahead of the influent to the first cell. By implementing PBII in the collection system, the solids degrading organisms increased in abundance before reaching the lagoon system.

Sludge depth measurements were taken in pond 1 in fall the year prior to treatment and the next two years with treatment. After a year of PBII applications, the depth of the solid sludge decreased about seven inches (Figure 8). By the third year of treatment, the sludge biologically degraded an additional three inches to an average sludge depth of 38 inches.

The POTW has not needed to mechanically dredge the lagoon system.

wastewater effluent remains high while solids are being biologically reduced. The lagoon facility continues bioaugmentation with BioLynceus® Probiotic Scrubber® II. The operators continue to monitor the sludge depth each fall following good practices.

Small Rural Community Avoids Dredging

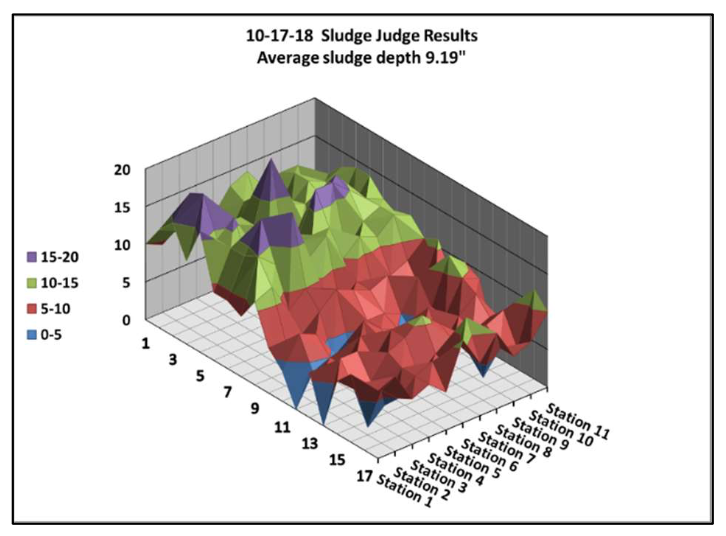

A small Wyoming municipality of 300 residents was having issues with accumulated solids in their 39-year old three-pond lagoon system. Each of the three ponds is 10 feet deep. The 0.01 MGD, system receives high organic loads that are not digested well by the resident microbiology. The ponds are equipped with aeration. Aeration is not being used at this time so the system is currently functioning as a facultative system. There is no headworks to provide any sort of pretreatment prior to reaching the lagoons’ ponds. Solids accumulated in the ponds reduced the wastewater holding and treatment capacity of the system.

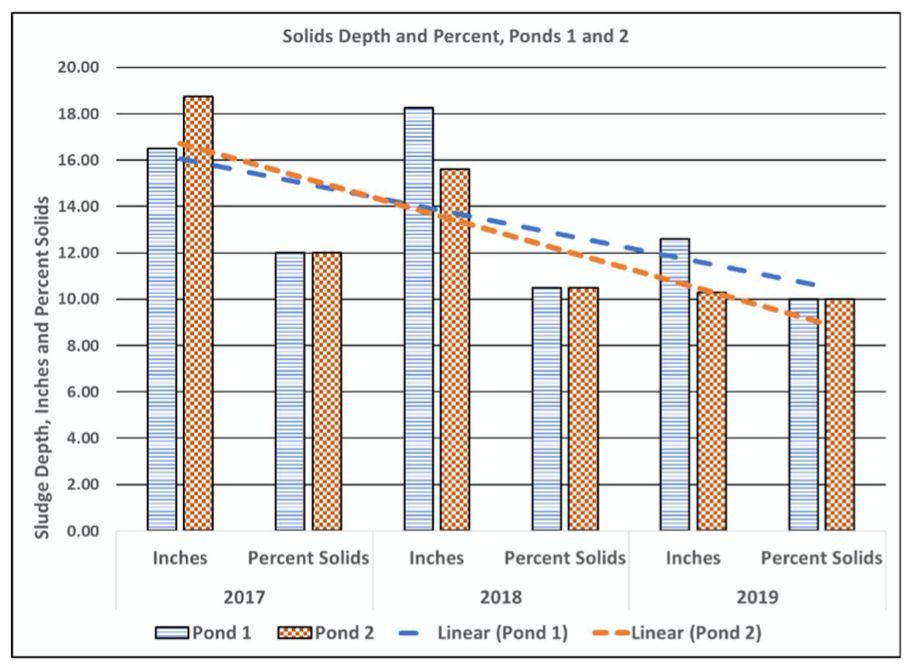

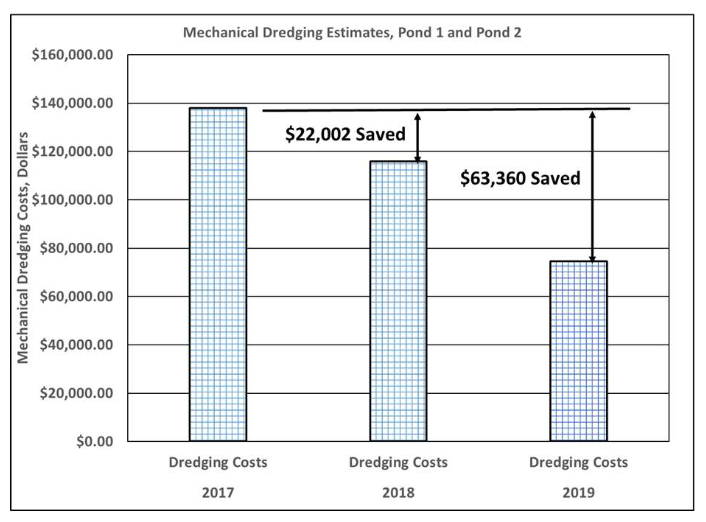

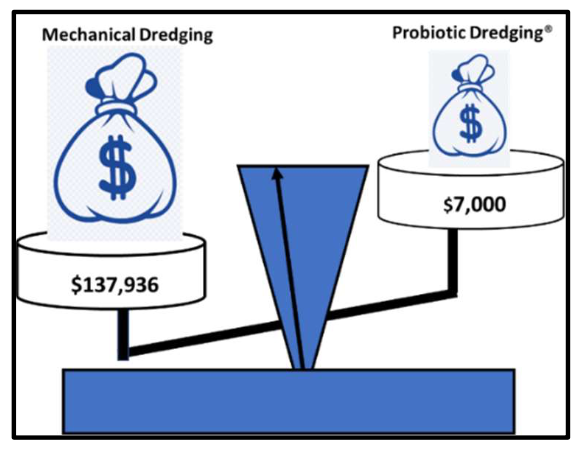

Bioaugmentation was suggested for the wastewatersystem to reduce dredging costs and improve solids degradation. A third-party estimate for dredging was $137,936. Management contacted BioLynceus® for live bacterial cultures to augment their lagoons. BioLynceus® Probiotic® II, a diverse consortia of wastewater bacteria, was implemented in the collection system to improve solids treatment.

Daily doses of PBII were drip fed into the system through a drain in the city hall basement, well ahead of the lagoon system. Over two years of treatment, solids were degraded in ponds one and two. The sludge in the first lagoon was bio-dredged an average of four inches in thattime.

Over the first year of treatment, sludge profiling of pond 2 revealed a three-inch average decrease in sludge depth. This pond was the most impacted by accumulated solids. The next year, the sludge depth was reduced by an additional five inches.

The density and appearance of the solids changed in both ponds one and two. During PBII treatment, the sludge was fluffier and shifted from a black to lighter brown color. This indicated better microbial digestion of the sludge. With greater space between solids particles, the wastewater bacteria more rapidly degraded the accumulated sludge.

Bioaugmentation helped improve the treatment capacity of the system without the cost of mechanical dredging. While applying PBII, solids in the lagoons were not manually removed.

Recall the estimated cost to dredge both cells prior to treatment was $137,936. This cost estimate was reduced to $74,576 – a 54% reduction – at the end of two years of treatment. To date they’ve still not dredged and thus have saved all of the original $137,936 estimate.

Over two years, the town spent approximately $7,000 on product. The return on investment (ROI)6 in the treatment has been phenomenal. Saving $137,936 with the $7,000 treatment cost in the two years is 2-year ROI of over 1870%! This is very significant for a town of any size.

Using PBII to degrade the accumulated solids has increased the available treatment capacity of the system. Probiotic Dredging® pays!

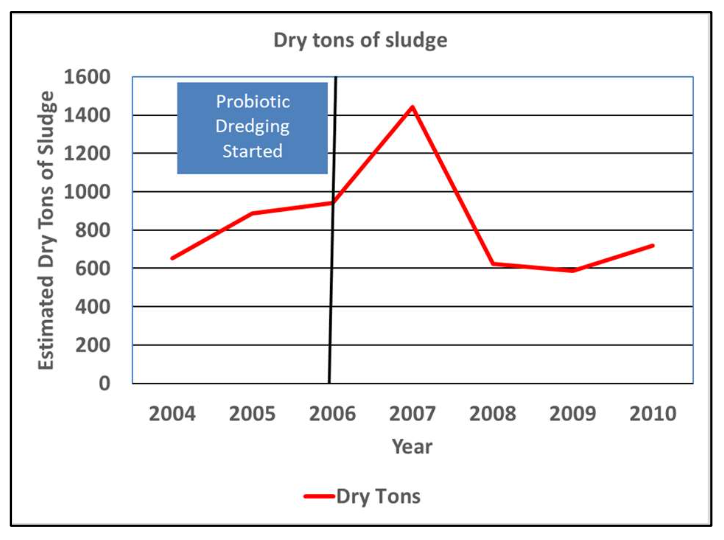

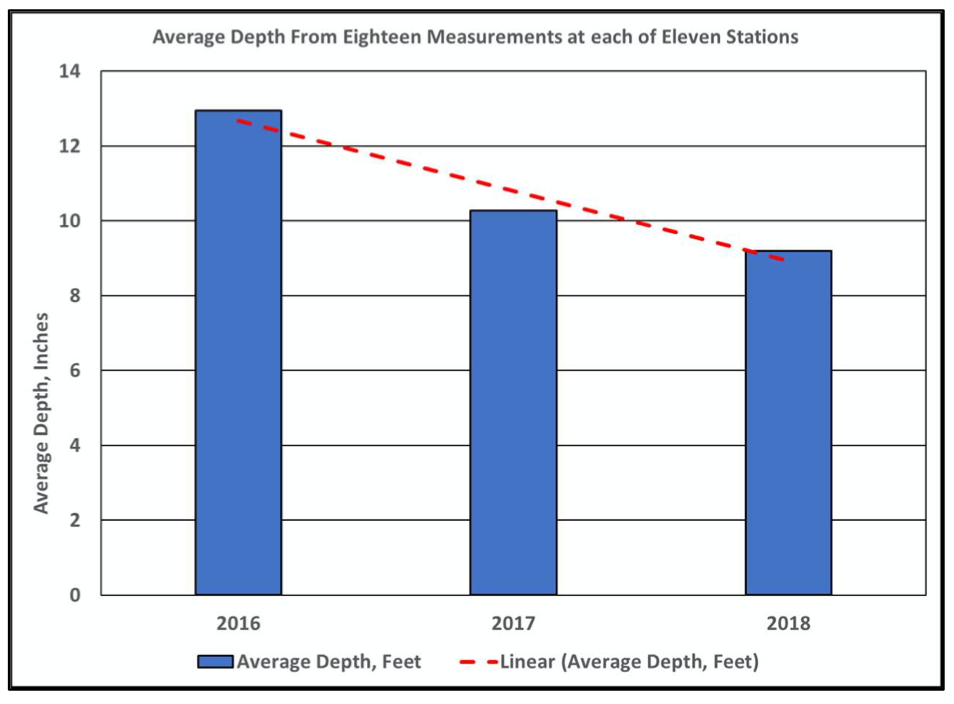

Utah Communities Team up to save with Probiotic Dredging®

A facultative wastewater treatment lagoon facility in northeastern Utah receives average flows of 0.9 MGD from two communities with a total population of approximately 7,500. The utility is designed as a zero direct discharge reuse plant. Wastewater influent first enters a 50-acre pond with mean-residence time of 120 days before moving to two 20.5-acre ponds and finally to 55-acre storage pond.

All discharge is either through surface evaporation or discharge to land application via a center- pivot irrigation system. The large capacity of the ponds is to enable the utility to hold the water when seasonal weather conditions make use of the center pivots impractical. Minimizing the volume occupied by sludge is therefore very important.

During the lagoon’s annual sludge inspection in 2016, the wastewater specialist for the Rural Water Association of Utah7 noticed there were excess solids accumulating. The sludge buildup was great enough to diminish the treatment capacity of the system. This issue could be solved by mechanical dredging. However, to delay the need for mechanical dredging, the lagoon operators sought a biological solution.

The wastewater managers decided to use BioLynceus® bioaugmentation. Probiotic Dredging® with PBII was implemented at the facility quickly.

The operators started treating the system with PBII, a concentrated live culture of wastewater bacteria. Product was applied to lagoon headworks from April to October. From November to March, PBII was dosed in the collection system.

Augmenting the lagoon collection system and headworks with ProBiotic Dredging® helped establish an effective wastewater biomass to slow sludge accumulation in the lagoon system. The utility continues to use bioaugmentation with PBII and it has not been necessary to mechanically dredge the ponds.

Solids and FOG Reduction in the Collection System and Wastewater Plant

Fats, oils, and grease (FOG) build-up in wastewater collection lines is a persistent issue that plagues many municipalities. Challenges arise when FOG and solids cause blockages in the sanitary sewers carrying influent flows to local treatment facilities. As greasy residues and solids accumulate, line jetting is often performed to eliminate troublesome build-ups. This option is expensive and time consuming. According to the US Environmental Protection Agency, the cost of hydro-flushing one foot of pipe ranges between $0.32and$1.008. Bioaugmentation can also be used to degrade greasy residues in collection infrastructure.

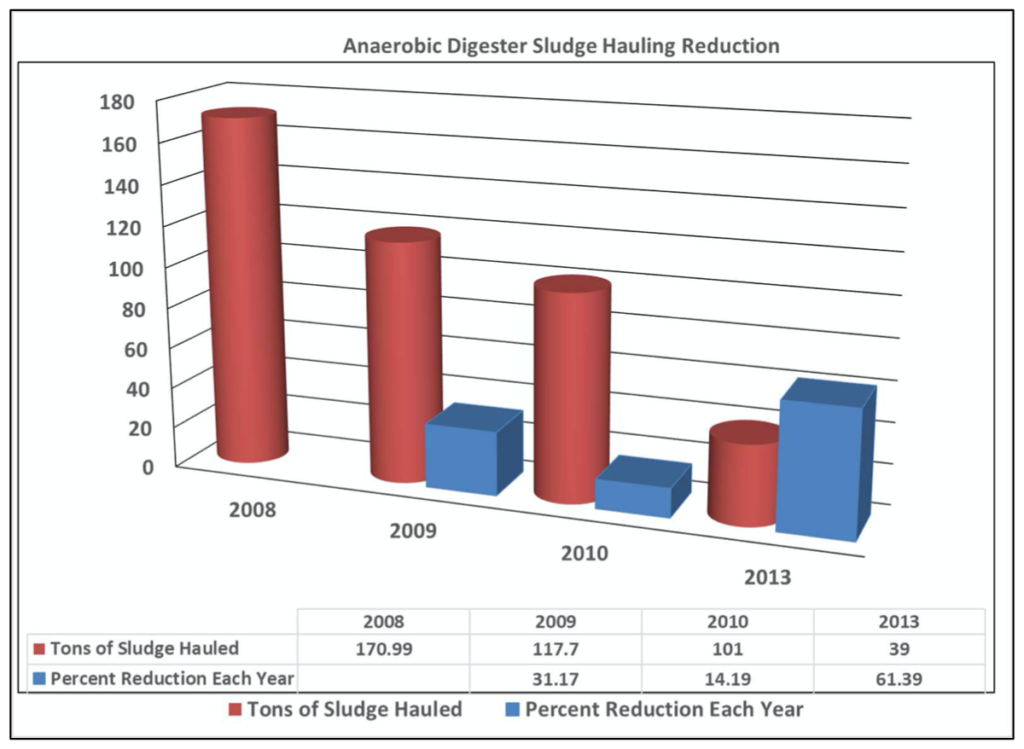

A small sanitation district in western Colorado operates a collection system and mechanical treatment plant with anaerobic digestion. The collection lines ahead of the 0.3 MGD mechanical wastewater treatment facility accumulated excessive sludge and FOG. If the buildup was left untreated the line could back-up causing a sanitary sewer overflow. Before jetting the lines, the sanitation district decided to try bioaugmentation to degrade the FOG. They used BioLynceus® ProBiotic Scrubber® II (PBII) to effectively reduce build-ups.

They began augmenting their system with PBII in two of the main collection trunk lines. The PBII treatment provided concentrated, live cultures of wastewater bacteria to break down the problem build-ups.

The bioaugmentation plan reduced FOG and sludge in the collection lines. The sanitation district supervisor explained, he did not need to jet the lines after using PBII in the collection system. Then, an unexpected dividend of the treatment was discovered – solids management costs at the mechanical plant decreased.

Solids management at wastewater treatment plants can be time consuming and expensive. The Environmental Protection Agency estimates the expense of biosolids handling and disposal made up 40% to 60% of the annual cost for treatment plant operations.9

The PBII fed in the collection system helped to reduce the quantity of wasted solids at the wastewater treatment plant.

The solids mass dried and vacated (SMDV) from the anaerobic digester was reduced by 31% in the first year. In the second and third years of treatment, the SMDV was decreased by 14% and 61%.

By reducing biosolids in the digester, bioaugmentation helped the facility save over $20,000 in removal fees in the first year. Improving biological solids degradation at the mechanical plant reduced the financial burden of wasted solids hauling and disposal.

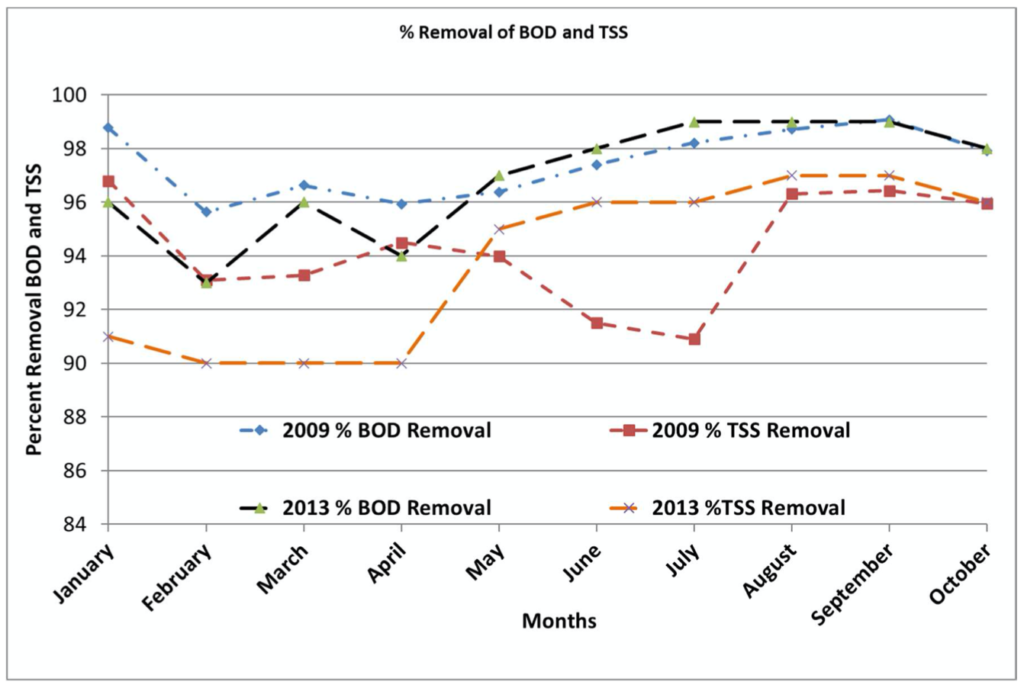

Reduction in solids and hauling costs cannot be at the expense of the primary mission of the treatment process, producing an effluent stream in compliance with regulations but most important, good for the receiving environment.

Augmenting the collection system with BioLynceus® cultures helped reduce FOG in the collection lines, reduce solids in the anaerobic digester, and minimized costs for jetting mains and hauling and disposal of digester solids. Most important high levels of treatment were maintained in the process.

Solids and Hydrocarbon Reduction in Oil Refinery Aerobic Biological Treatment Units

A petroleum refinery in New Mexico relies heavily on three aerobic biological treatment units (ABTUs) – lagoons – to process their high strength wastewater. The ABTU’s are designed for a flow of 2 MGD. The refinery processes 45,000 barrels of crude oil a day.

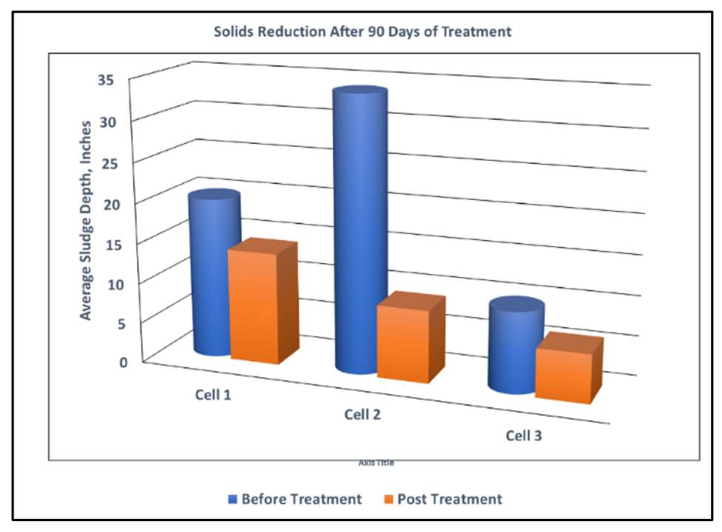

Issues developed in the first treatment cell. A chemical reaction caused the sludge in the basin to seal with a hard calcium crust. This inhibited the biological treatment in the first ABTU. A mixed hydrocarbons and solids sludge began rapidly accumulating in the second and third cells. The capacity of the system was decreased along with the mean cell residence time. As a result, the treatment was failing in the ABTUs which caused the facility to operate out of permit compliance. In need of a biological solution, the refinery contacted BioLynceus®.

To better understand the problem, a BioLynceus® representative performed an onsite assessment of the aerated lagoon system. He assisted the operators with breaking up the calcium layer in the first basin and evaluated the sludge levels. The refinery decided to use bioaugmentation at the ABTUs. BioLynceus® ProBiotic Scrubber® HCC (PB – HCC) was recommended by the BioLynceus representative to:

- decrease the solids and oil residues in the treatment process and

- bring the effluent within permit compliance.

The PB – HCC seed contains a concentrated live consortium of wastewater treating bacteria.

PB – HCC was inoculated ahead of the American Petroleum Institute separator in the headworks to begin treatment. A dose of product was administered daily. Within 90 days, PB- HCC helped reduce the sludge depth by 30% in pond 1, 73.5% in pond 2 and 40% in pond 3. The treatment system effluent was brought within permit compliance.

The BioLynceus® product reduced the solids in the ABTU system enough to continue treating the influent without shutting down for emergency dredging. Minor dredging operations were completed while the lagoon system continued to process wastewater. The Environmental Manager at the refining company commented, “The refinery has saved a tremendous amount not only in money but also in down time.”

Over three months of treating the ABTUs, sludge depth was reduced, wastewater discharge was brought within permit limits, and dredging costs were decreased. The aeration basins were not shut down for extensive dredging. This permitted influent wastewater processing while the sludge issue was resolved. Augmenting with PB-HCC increased the functional biomass in the system and promoted efficient hydrocarbon and solids removal.

Complementary technologies help municipal and industrial treatment systems

All lagoons, municipal or industrial will have to be mechanically dredged to remove accumulated sediment. It is prudent to ensure the solids have been well digested by the microorganisms. Bioaugmentation assists in achieving this first important goal so that solids removed later by mechanical dredging are well stabilized and more friendly to the receiving environment. Bioaugmentation and mechanical dredging are complementary technologies.

The municipal and industrial applications described in this document demonstrate the efficacy of using bioaugmentation – Probiotic Dredging® – to effectively manage sludge in lagoons, solids and FOG in collection systems and mechanical wastewater plants and difficult to treat industrial waste, such as at a refinery. Contact BioLynceus to see if Probiotic Dredging® can save you time and money. See if Probiotic Dredging® will assist your utility in returning well stabilized solids to the receiving environment.

ProBiotic Scrubber® is a registered trademark of BioLynceus® LLC ProBiotic Dredging® is a registered trademark of BioLynceus® LLC BioLynceus® is a registered trademark of BioLynceus® LLC ©Copyright October, 2020 by BioLynceus® LLC, all rights are reserved.

References

1 USEPA Wastewater Technology Fact Sheet, Facultative Lagoons, https://www3.epa.gov/npdes/pubs/faclagon.pdf

2 USEPA Wastewater Technology Fact Sheet, Facultative Lagoons, https://www3.epa.gov/npdes/pubs/faclagon.pdf

3 Sludge Judge® is a trademark of Environment Remediation Equipment, Inc.

4 The Wyoming Association of Rural Water Systems (WARWS) is an affiliate of the National Rural Water Association(NRWA). NRWA has affiliate organizations in all fifty states. NRWA and its state affiliates comprise the largest utility membership organization in the United States representing nearly 31,000 small and rural water and wastewater systems that serve over 1/3 of all Americans. They provide technical assistance to member utilities in water and wastewater treatment, utility operation, obtaining grants, and technical training. Utilities serving a population less than 10,000 are eligible to join as full voting members of their state affiliate.

5 Gerardi, M. (2016). Wastewater Bioaugmentation and Biostimulation. Lancaster, Pennsylvania: DEStech Publications, Inc. Pp.117

6 %ROI = ((Current Value of Investment – Cost of Investment)/Cost of Investment) X 100

7 The Rural Water Association of Utah is an affiliate of the NRWA.

8 Collection Systems. O&M Fact Sheet. Sewer Cleaning and Inspection (1999). United States Environmental Protection Agency. Office of Water, Washington, D.C.

9 U.S. Environmental Protection Agency. (1985). Estimating Sludge Management Costs Handbook. Cincinnati, OH: Center for Environmental Research Information.

10 Mud Cat is a registered trademark of Ellicott Dredge Technologies. The MC-40E is one of five 20-100 hp electrically powered dredges. Mud Cat® also offers larger dredges operating on diesel power.

[/et_bloom_locked]