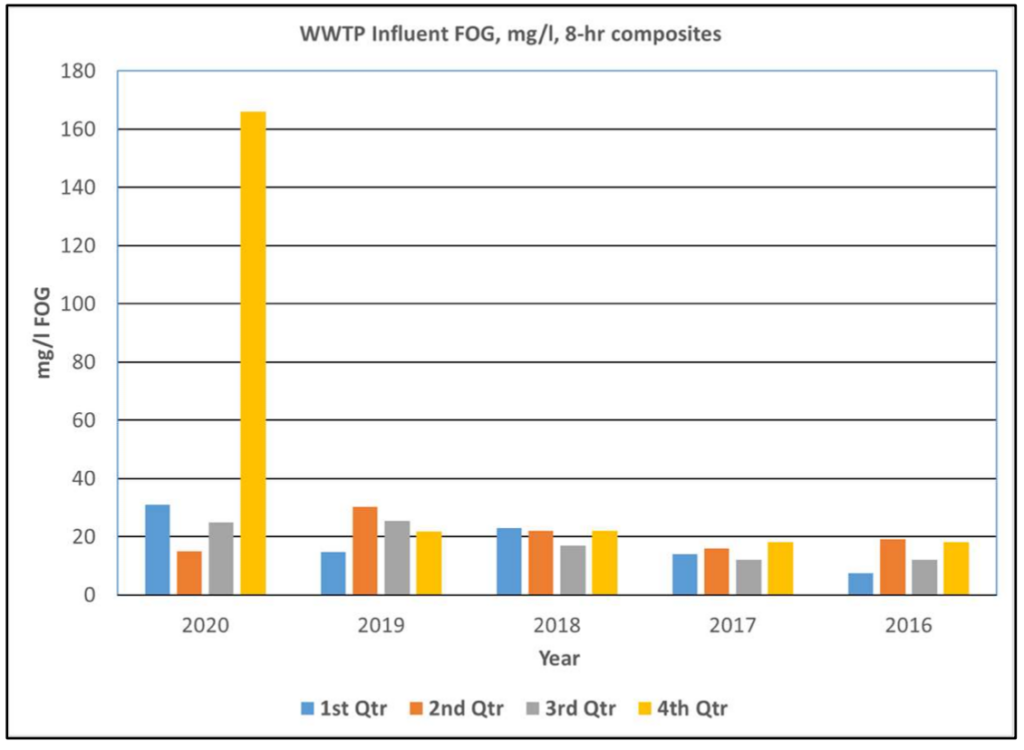

FOG formation, accumulation and consequences

FOG, fats, oils and grease create a variety of problems in sewer collection piping, lift stations and wastewater treatment plants. The most benign result of FOG maybe increased treatment cost at the wastewater plant.

In the collection system more costly and serious problems include clogged or severely restricted flow in sewer lateral lines as well as the main line and clogged sewer lift stations.

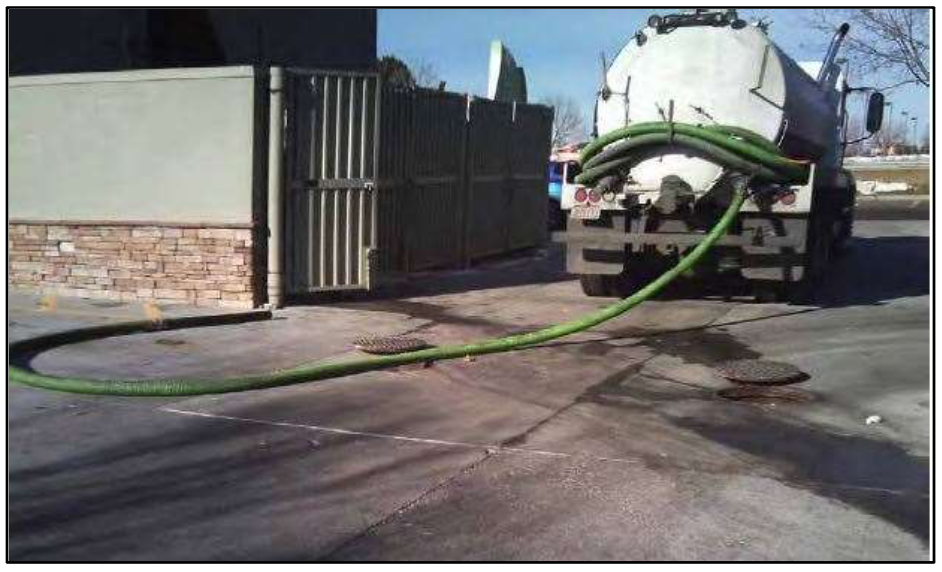

It is common practice to attempt to maintain the FOG at no more than 25% of a GI’s total volume. So, when 25% full of FOG both the FOG and liquid are pumped from the tank by a commercial hauler.

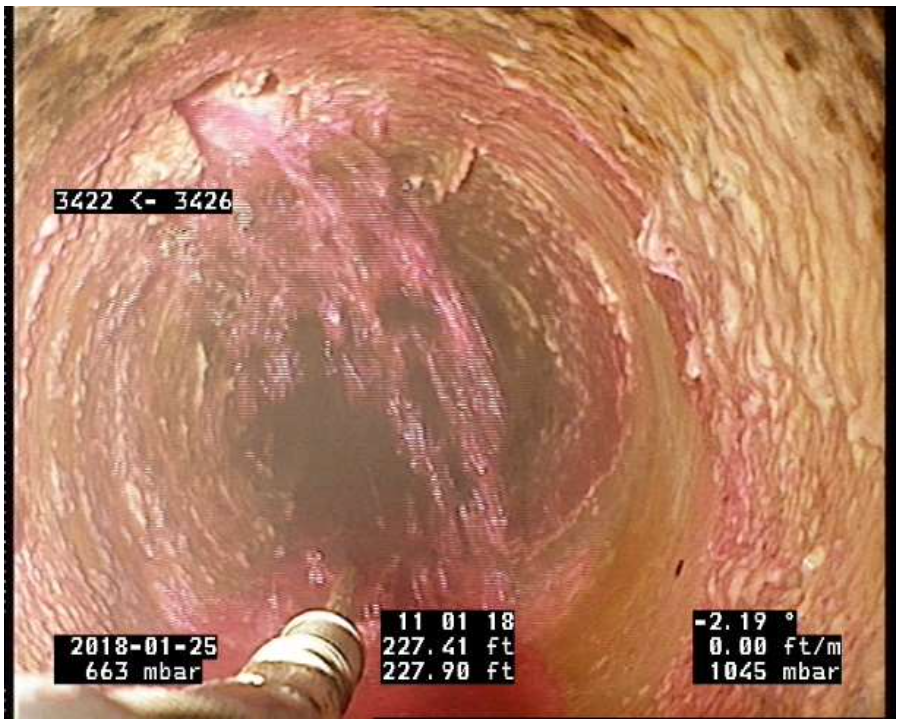

Perhaps the costliest consequence of FOG is corrosion to metallic as well as concrete piping and structural components in the sewer collection system.

What causes FOG build up?

It seems pretty straight forward. One can easily visualize the meat fats, cooking oils and grease that enter the sewer system from private homes as well as commercial eating establishments and other commercial businesses and industries.

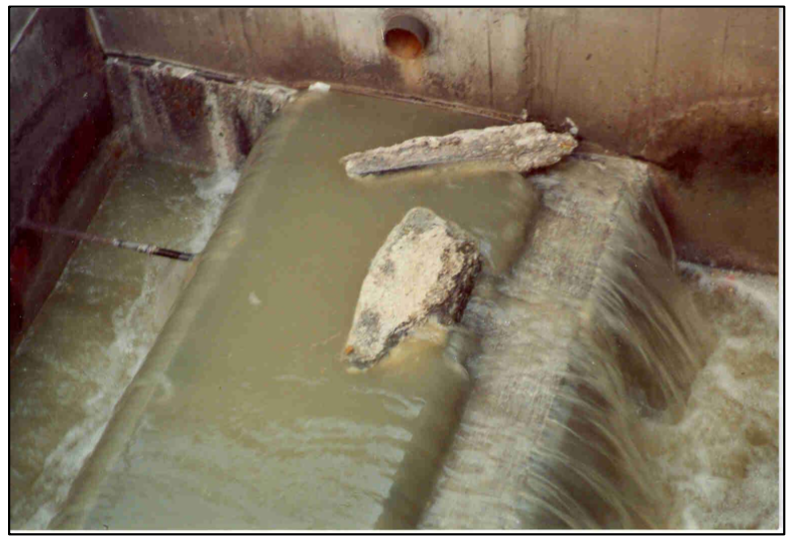

But those visual images do not match the FOG as it often appears in a sewer.

Making soap

Fat, oil and grease that enter the sewer undergo a chemical reaction known as saponification – making soap. Soap has been made for centuries using a fat (typically lard) and a base (alkali) – typically, sodium hydroxide aka lye. Dr. Joel Ducoste lead a study 2013 to better understand the FOG deposits and saponification in sewers.2 The actual chemical reaction is somewhat complex but saponification can be simply stated as a reaction that converts fat, oil and grease into a soap in the presence of an alkali. In a sewer, the source of the alkali is the calcium (e.g. calcium carbonate and calcium sulfate) contributed by other products in the waste stream or the water itself (e.g. water hardness). Unfortunately, the bulk of the calcium needed for the reaction is contributed by the concrete piping and concrete structures in the sewer system. Additional factors which influence FOG formation include temperature, pH, the type of fat, oil or grease and the physical characteristics or hydraulics of the sewer system.

Dealing with FOG, the brute force alternative

Understanding FOG deposits is interesting. It is a problem of chemistry and by necessity, biology. But the typical approaches to dealing with FOG may be described as education and use of brute force.

2 Factors that influence the Formation of FOG Deposits in Sewer Collection Systems, North Carolina State Univ., EPA Research Forum Advancing Public Health Protection through Water Infrastructure Sustainability, April 10-11, 2013, Arlington, VA.

In spite of efforts to educated the users of the sewer system, the wastewater utility will still need to have an arsenal of equipment for the brute force alternative.

Dealing with FOG, the biological alternative

Bioaugmentation can be very valuable in reducing the costs of dealing with FOG. With bioaugmentation the oils, fats and grease are reduced (digested) by microorganisms before they become the saponified, troublesome soapy deposits.

Bioaugmentation can be used to reduce FOG in collection systems and minimize maintenance requirements. Augmenting lift stations and sewer pipes with cultures of wastewater bacteria solubilize and degrade FOG to decrease accumulation.3

Bioaugmentation will not completely eliminate the need to jet or vacuum clean sewer system components. But as can be seen in the following case studies, bioaugmentation can significantly reduce the cost and frequency of the brute force alternative.

Bioaugmentation in a 0.7 MGD collection System

The wastewater utility provider for a city of 10,000 residents in Arizona was having issues with FOG accumulation in their collection system. The system averaged 0.7 MGD wastewater flows. Several of the collection lines and main lift station were coated with thick greasy residues that required frequent cleaning.

One sewer line, particularly prone to FOG buildups, was receiving wastewater inputs from a concentrated cluster of restaurant establishments. The pipe required monthly jetting to maintain flow. Additionally, the down-line lift station frequently needed cleaning. The wastewater managers tried using a citrus based product to dissolve the grease. However, the citrus degreaser did little to remove FOG and caused additional corrosion to the cables and floats in the lift station. The operations management needed an effective solution to reduce the frequency of collection system maintenance.

The municipality decided to use bioaugmentation to manage the persistent grease. They implemented BioLynceus® Probiotic Scrubber® II (PBII) in the sewer main and adjacent lift station receiving the heaviest FOG loadings. PBII contains highly diversified and concentrated cultures of living bacteria selected to solubilize and degrade grease. PBII is safe for equipment, the people who handle it and the environment.

Within 2 months of treatment, 80% of the grease that previously collected in the pipe had disappeared. The sewer line no longer needed to be jetted monthly to prevent back flow. Furthermore, the lift station accumulated less FOG and what matter did accumulate was easier to remove.

Maintenance of the lift station was minimized. There was no damage to lift station components. Augmenting the collection system with Probiotic Scrubber® II helped reduce FOG accumulation and associated operational challenges.

FOG reduction in a 0.8 MGD collection system reduces lift station maintenance

A growing Wyoming municipality of 10,000 people was having trouble with fats, oils, and grease management in their wastewater collection system. The city’s lift stations and main lines were consistently coated with grease. When the lift station pits were cleaned each year, the FOG was so thick, manual scraping was required to remove the residues. The wastewater supervisor was interested in using bioaugmentation to reduce FOG in the lift stations. He contacted BioLynceus® for a reliable biological solution.

BioLynceus® ProBiotic Scrubber® II (PBII) was implemented for one month to test the efficacy of the product for reducing FOG. The PBII contains a highly diversified consortium of living bacteria for augmenting wastewater systems. Regular dosing of PBII was completed at one lift station impacted with high FOG contamination.

Within the first month of treatment, the operators noticed a considerable improvement in the amount of FOG collecting in the lift station and it was also a lighter color and softer in texture.

The wastewater management was pleased with the FOG reduction. However, they decided to stop adding PBII to the lift station to see if FOG would accumulate again. FOG began to build up in the lift station after a few weeks without BioLynceus® product. In response, the wastewater management decided to resume using PBII at the original location. Plus, they added PBII to three of their lift stations in the winter and four in the summer.

Two months after treatment was resumed, the jet truck operator arrived at the facility to clean the lift stations. To his surprise, the pits had less grease and paper products than ever before. The FOG that remained in the stations was easily sprayed off without mechanical removal or use of a degreaser. The treatment ensured ease of cleaning when the time came for routine maintenance of the lift stations. Additionally, when the collection lines were jetted months later there was less grease than in previous years.

Another benefit was, the PBII treatment helped reduce FOG without the use of chemical degreasing agents. Chemical degreasing agents can cause toxicity in the treatment process down line. The head wastewater operator for the city’s treatment facility wrote, “The other good thing about this product is that it is environmentally friendly and safe to use.” ProBiotic Scrubber® II mitigated the FOG from the collection system, providing on-going support of FOG removal from the system.

FOG reduction in the collection system; solids reduction in the digester

Challenges arise when FOG deposits and other solids cause blockages in the sanitary sewers. As greasy residues and solids accumulate, line jetting is often performed to eliminate troublesome build-ups. This option is expensive and time consuming. According to the US Environmental Protection Agency, the cost of hydro-flushing one foot of pipe ranges between $0.32 and $1.00.4 Bioaugmentation can also be used to degrade greasy residues in collection infrastructure.

A small sanitation district in western Colorado operates a collection system and mechanical treatment plant with anaerobic digestion. The collection lines ahead of the 0.3 MGD mechanical wastewater treatment facility accumulated excessive FOG and other solids. If the buildup was left untreated the line could back-up causing a sanitary sewer overflow. Before jetting the lines, the sanitation district decided to try bioaugmentation to degrade the FOG. They used BioLynceus® ProBiotic Scrubber® II (PBII) to effectively reduce build-ups.

They began augmenting their system with PBII in two of the main collection trunk lines. The PBII treatment provided concentrated, live cultures of wastewater bacteria to break down the problem build-ups.

The bioaugmentation plan reduced FOG and sludge in the collection lines. The sanitation district supervisor explained, he did not need to jet the lines after using PBII in the collection system. Then, an unexpected dividend of the treatment was discovered – solids management costs at the mechanical plant decreased.

The PBII fed in the collection system helped to reduce the quantity of wasted solids at the wastewater treatment plant.

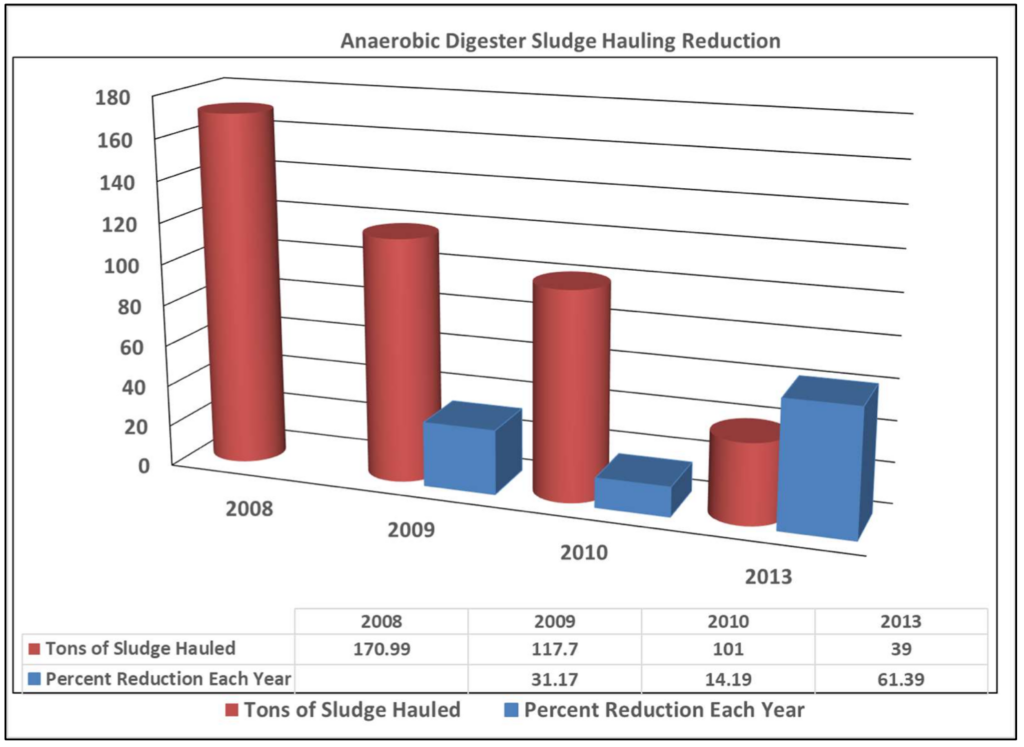

The solids mass dried and vacated (SMDV) from the anaerobic digester was reduced by 31% in the first year. In the second and third years of treatment, the SMDV was decreased by 14% and 61%.

By reducing biosolids in the digester, bioaugmentation helped the facility save over $20,000 in removal fees in the first year. Improving biological solids degradation at the mechanical plant reduced the financial burden of wasted solids hauling and disposal.

Small community fights FOG with Probiotic Scrubber® PP

A small community in Colorado’s San Luis valley is battling FOG with limited resources. The town manager said, “We’re a small community of about 400 homes and a dozen businesses. We just replaced our old clay tile sewer piping and improved our water system too. Now we have this challenge.”

At the same time the sewer mains were replaced a lift station was added. The waste flows from the lift station to two aerated lagoons operating in series. Each lagoon is approximately 5 acres and is 5 feet deep. Daily flow in the system ranges from 0.17 to 0.20 MGD. Design capacity is 0.4 MGD.

During the summer of 2020 they noticed considerable buildup of FOG at the lift station and there was visible oil sheen around edges of the lagoons. The town manager reported, “while inspecting the new lift station we noticed the FOG was climbing the walls and other parts of the lift station.

The town manager and maintenance director heard about bioaugmentation for fat, oil and grease at a local rural water conference. “The BioLynceus representative visited our site.

Based on the amount of FOG build up and the sheen at the lagoons, he recommended Probiotic Scrubber® PP (PBPP).”

The PBPP product is similar to the PBII but contains an added population of organisms that are especially effective in handling heavy grease accumulation. “We’ve added the product now for three months and are happy with the results and will continue to use it for control of our FOG”, the town manager indicated.

A BioLynceus representative can assist customers in selecting the right product for a particular site. Just because a particular product may work well at one lift station doesn’t necessarily mean it will work as well as the next. In this case the PBPP product was just the right call.

Fat, oil and grease – FOG – in a sewer system creates multiple problems including:

- clogging of sewers causing reduced flow or complete blockage.

- creation soapy deposits that are difficult to remove.

- Increased maintenance of lift station equipment.

- Corrosion of metallic structures.

- Corrosion of concrete structures and piping.Controlling FOG involves education of the residential, commercial and industrial customers to limit introduction of FOG to the sewer. Sewer jet and vacuum trucks are indispensable tools but expensive to own and maintain. Using bioaugmentation to digest and thus reduce the FOG can reap considerable savings in jetting, pumping, hauling and also in damage from the corrosive effects of FOG.

Talk to a BioLynceus® representative to see if bioaugmentation can help minimize the costs for FOG remediation in your system. One size doesn’t fit all. A BioLynceus® representative will recommend the best product to address your particular need.BioLynceus® and ProBiotic Scrubber® are registered trademark of BioLynceus® LLC ©Copyright December, 2020 by BioLynceus® LLC. All rights are reserved.

FOOTNOTES

1 Photos and data used in Figures 1-12 were provided courtesy of Bill Thomas. Used with permission.

2 Factors that influence the Formation of FOG Deposits in Sewer Collection Systems, North Carolina State Univ., EPA Research Forum Advancing Public Health Protection through Water Infrastructure Sustainability, April 10-11, 2013, Arlington, VA.

3 Gerardi, M. (2016). Wastewater Bioaugmentation and Biostimulation. Lancaster, Pennsylvania: DEStech Publications, Inc. Pp. 109, 113.

4 Collection Systems. O&M Fact Sheet. Sewer Cleaning and Inspection (1999). United States Environmental Protection Agency. Office of Water, Washington, D.C.