biological denitrification technology

“The biological denitrification technology is based on the conventional theory that carbon is the limiting factor in the efficiency of biological denitrification. Heterotrophs utilize carbon from organic compounds like sugars, organic acids and amino acids as source of electrons rather than from inorganic compounds like carbon dioxide…[1]

Heterotrophic bacteria obtain sugars (food) from their environment. Heterotrophic organisms responsible for denitrification can be further described as anaerobic facultative bacteria; that is, they can thrive in anaerobic or anoxic environments.

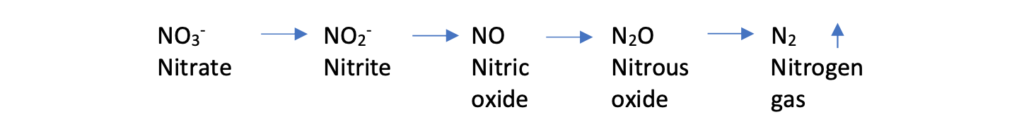

The reaction sequence for nitrate removal by heterotrophic bacteria is illustrated in the following equation:

[2]Figure 1: Reaction sequence for nitrate removal by heterotrophic bacteria

For many municipal wastewater treatment (POTWs) facilities removing inorganic nitrogen to meet permitted discharge levels can be a difficult requirement. Discharging nitrate loads into surface waters can have adverse impacts on aquatic environments, including eutrophication and toxic algal growths. Controlling nutrient discharges is also an issue for industrial wastewater treatment facilities.

POTW’s and industrial treatment facilities strive to keep their biological treatment functioning properlysothesesortsofissuesdon’tarisedownstreamfromtheirdischargepoint. Equipping facilities with biological nutrient removal (BNR) capability will aid utilities in controlling nitrogenous species in wastewater effluent.

Figure 2: BNR is important in achieving an effluent from a municipal or industrial wastewater treatment facility low in nutrients. Nitrogenous species can create undesirable impacts on the aquatic environment and the animal and plant life that depend on clean water.

For denitrification to proceed efficiently, there are several environmental conditions wastewater treatment facilities must maintain and consider. These conditions include:

- – Sustaining an adequate abundance of denitrifying bacteria (DB) in a biomass

- – Forming an anoxic zone,

- – Provide consistent organic carbon inputs to the anoxic process.

Organic carbon availability in the anoxic process is a limiting factor for denitrification.

carbon substrate is often exhausted in the aeration process in activated sludge systems leaving very little to support denitrification. Previous studies have found that augmenting with external [3]

organic carbon is necessary to achieve optimal nitrate removal.

Candy Carbon®: Supplementing organic carbon

Candy Carbon® is an external organic carbon (EOC) product used by wastewater facilities to enhance biological processes and increase organic carbon when and where needed. This product has been demonstrated to provide adiverse bacterial population for enhanced denitrification and balancing bacterial community dynamics in diluted systems.

Enhancing Denitrification

Van Trump et al. 2011, identifies the role of humic acid in stimulating denitrification processes in saturated soil systems. Furthermore, this study indicates humic acid promotes development of a bacterial community enriched with a diverse population of denitrifying genera[4]

.

Because denitrifying bacteria in wastewater systems are derived from soils and sediments of freshwater lakes and streams, the results of Van Trump’s study may be extended to wastewater treatment. Candy Carbon (CC) contains natural humic material which, like humic acids in soils, may promote a more diverse and stable community of denitrifying bacteria in wastewater than the simple organic carbon substrates frequently used. Because of these multifunctional capabilities of CC, it takes a lot less CC to accomplish the same result as products typically dosed on COD content only, e.g. methanol. For example, one activated sludge facility implemented CC to stabilize F:M in their system after high infiltration and inflow events. The utility was able to feed approximately 84% less Candy Carbon than the supplement they’d previously been using.

Balancing F:M ratios

Wastewater treatment plants with low F:M ratios (food to microorganism ratio) can benefit from additions of organic carbon. When influent BOD/COD is too low to support the biomass, the organisms begin to function sluggishly and will eventually die. Stressed activated sludge generally does not settle well and can cause additional treatment issues.

Influent BOD may drop off when the service area population is intermittent (resorts), there is high infiltration and inflow (I&I), and/or the facility is over-designed for the current population or use. The nutrient load can be supplemented with external organic carbon to keep the biomass alive and active until the influent BOD is adequate to provide the proper F:M.

Safe for the Process, Operator and Environment

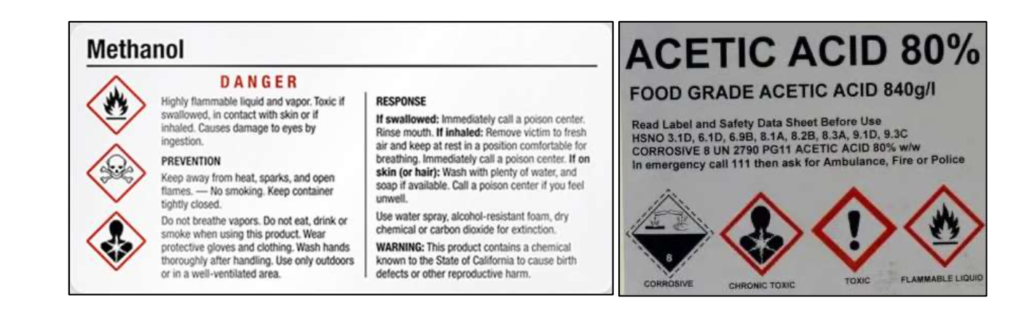

Candy Carbon is safe for aquatic organisms, storage, and operator handling. Product contents are never flammable or corrosive like alternative EOC supplements.

Figure 4: Some EOC alternatives such as methanol and acetic acid may be toxic, flammable and require special handling and storage. Other EOC supplements may be synthetic chemicals that may cause operational challenges like clogged membrane filters. BioLynceus Candy Carbon is safe for the environment and the persons handling it.

Camp Verde Denitrification with Candy Carbon

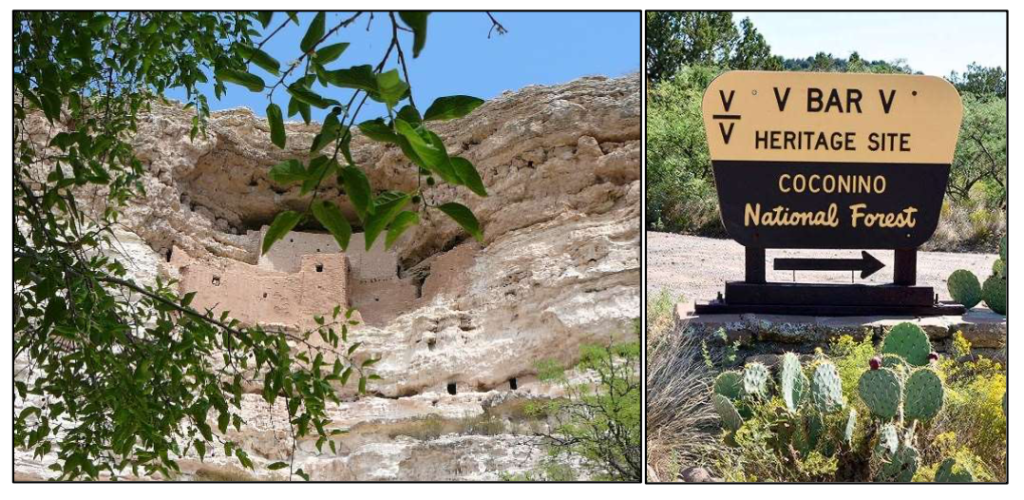

Camp Verde, AZ is a small community of about 11,000 individuals. Located near the geographic center of Arizona the area attracts many visitors for recreation, museums, and historic sites including Montezuma’s Castle National Monument.

Figure 5: Montezuma’s Castle National Monument near Camp Verde is maintained by the National Park Service. The area has many other attractions including local, State and Federal sites and facilities. The National Forest Service maintains The V Bar V Heritage Site. It is the largest known petroglyph site in the Verde Valley of central Arizona.

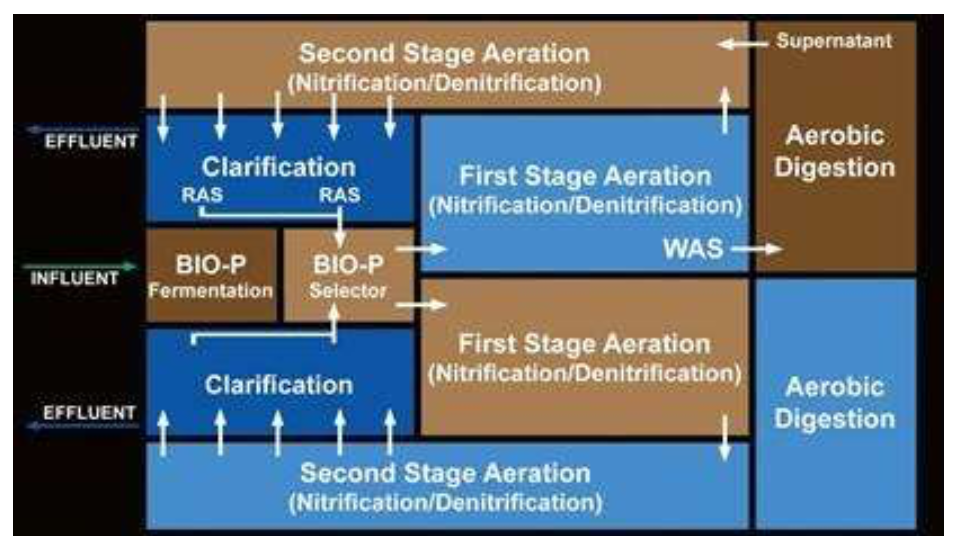

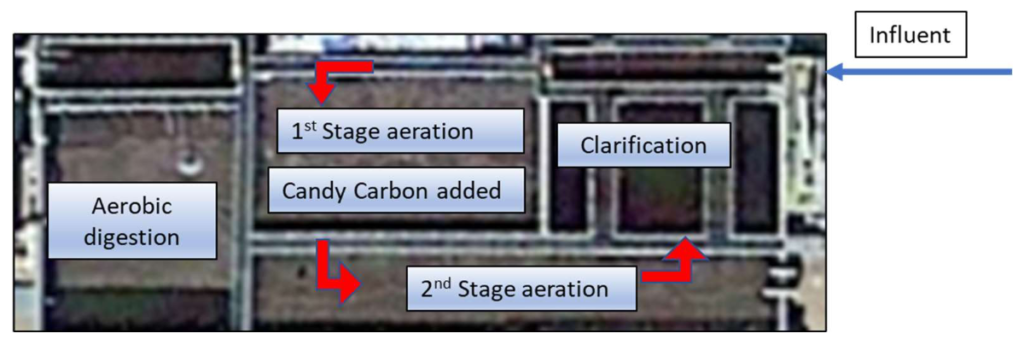

The wastewater utility uses an Aero-Mod® aerobic treatment system that utilizes a Sequox®5 system for nitrification/denitrification.

The system is currently under loaded. Designed for a flow of 0.65 MGD, the average flow is about 0.24 MDG. Only one side of the dual stream system is in service. The influent is low in BOD. The F:M is out of balance. There is simply not enough food (available carbon sources) available for the microorganisms to accomplish successful denitrification.

A BioLynceus® treatment regimen was implemented in early 2015. The utility continues to use the products to maintain compliance.

The utility has a two-fold treatment system. First, Probiotic Scrubber® N (PBN) is introduced upstream at a lift station approximately one mile from the treatment plant. The time of transit to the plant provides a time for pretreatment. Continuous metering of PBN provides a healthy population of organisms as they enter the treatment facility.

Influent pretreated with PBN enters the Aero-Mod Sequox/Plus module where BioLynceus Candy Carbon (CC) is added in the 1st stage aeration.

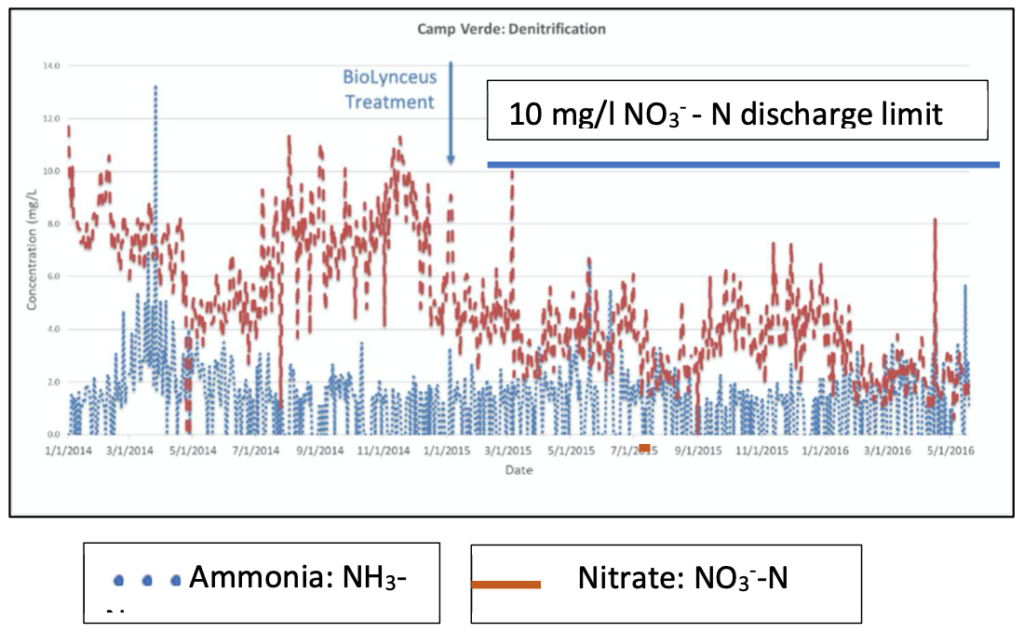

Within days, the concentrations of nitrate in the facility’s effluent were significantly decreased. The monthly concentration of nitrate removed was increased during CC treatment. The greatest monthly increase in removal experienced between the pre-treatment and treatment years was in July, 16 mg/L, and the least was in January, 0 mg/L.

Results of the addition of CC are illustrated in Figure 11. Continuing the treatments with PBN as a pretreatment at the lift station and CC in 1st aeration basin has permitted the NO3—N to remain consistently below the discharge limit of 10 mg/l and normally less than 6 mg/l.

Denitrification with Candy Carbon® at an Industrial Wastewater Treatment Plant

Industrial wastewater can often be deficient in organic carbon substrate. Lack of a carbon source limits biological denitrification in industrial wastewater treatment just as it does in municipal systems. Addition of a supplemental carbon source can improve the efficiency of the industrial wastewater treatment process.

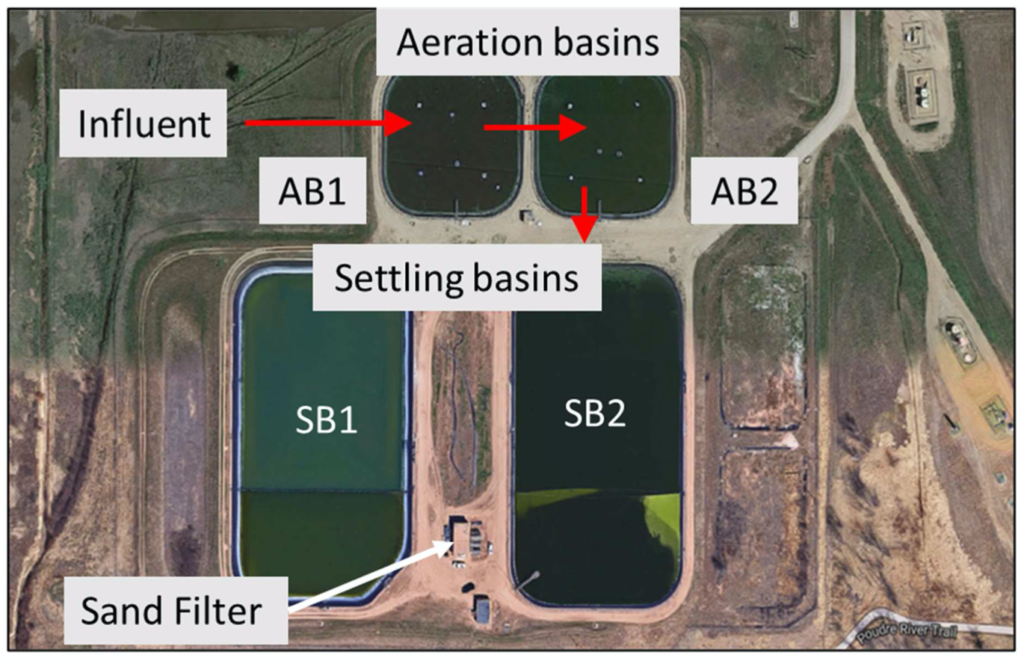

A 0.7 MGD out-door industrial wastewater treatment plant (IWTP) experiences difficulty with achieving biological nutrient removal. The facility, see Figure 12, is comprised of two aeration basins, AB1 and AB2, two settling basins, SB1 and SB2 and a sand filters for tertiary treatment before discharge to a river. Aeration is provided by four floating aerators per aeration basin.

The facility is operated with the two aeration basins in series followed by settling and filtration. Either aeration basin can be operated as aerobic or anoxic. During the study described here, influent entered AB1 which was being operated as an anoxic cell. The treatment then proceeded to AB2 operating as an aerobic cell. Effluent from AB2 was directed to either SB1 or SB2. Only one settling basin is used at any one time.

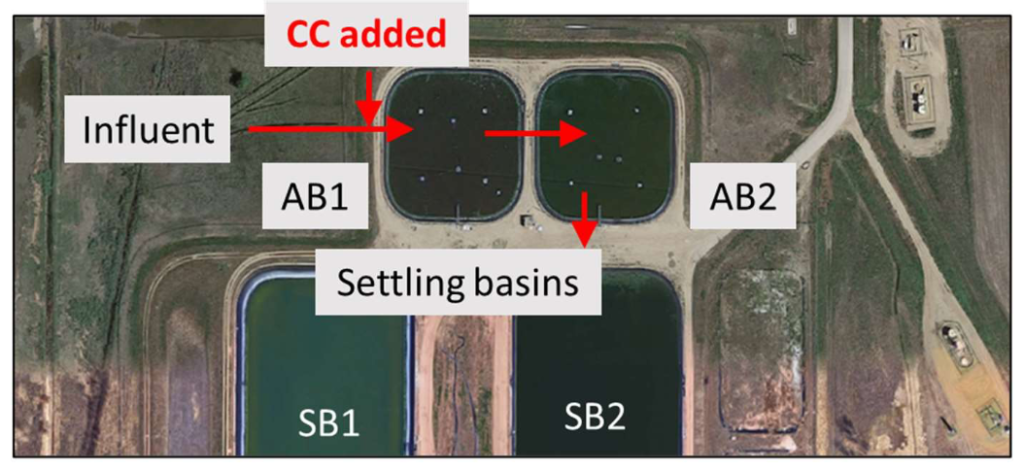

Nitrification was facilitated in the aeration basin, AB2, but denitrification was not occurring in the anoxic treatment cell, AB1. This caused the discharge to the plant’s settling basin to be high in nitrate. Seeking advice on the issue, the head operator at the facility contacted a BioLynceus® representative. BioLynceus suggested investigation to determine if the organic carbon loading to the denitrification basin was too low. Indeed, the biology needed a supplemental carbon source to carry out denitrification.

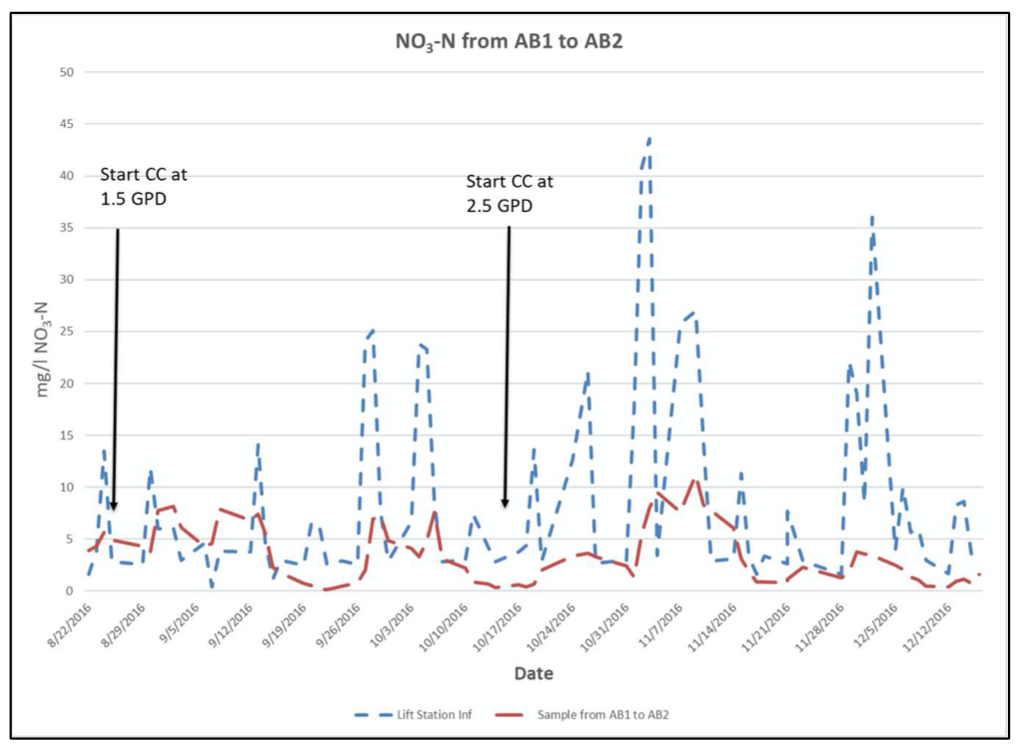

The data illustrated in figure 14 demonstrate the positive impact from adding Candy Carbon as a supplemental carbon source at AB1. While significant spikes occurred in the influent nitrate to AB1, the effluent from AB1 to AB2 remained relatively consistent averaging around 5 mg/l.

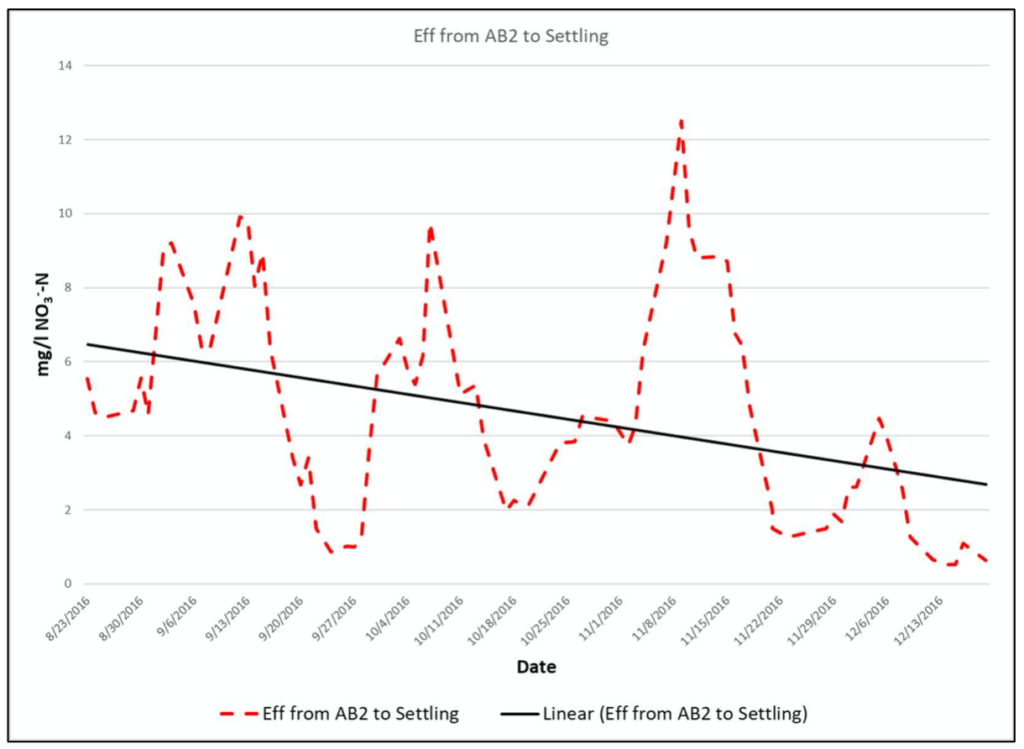

Improved denitrification helped to reduce nutrient loading to the settling basin. The trendline illustrated in Figure 15 clearly demonstrates the decreased in the amount of nitrate reaching the settling basin. As a result of the Bio Lynceus Candy Carbon treatment, the IWTP effluent was higher quality.

BioLynceus® provided the facility with a high strength organic carbon source for efficient denitrification.

BioLynceus Candy Carbon was the key to these facilities achieving and maintaining satisfactory denitrification. The treatment facilities were able to maintain compliance with discharge limits and probably more important, discharge an effluent that was good for the aquatic environment.

References

1 Use of an external organic carbon source in the removal of nitrates in bio-sand filters (BSFs). C Mutsvangwa and E. Matope Department of Civil Engineering & Surveying, Cape Peninsula University of Technology. Water Eng. Sci., 10, 119–127, 2017

2 Gerardi, M. (2006). Wastewater Bacteria. Hoboken, New Jersey: John Wiley & Sons, Inc.Pp.86.

3 United States Environmental Protection Agency (EPA). (2013). Wastewater Treatment Fact Sheet: External Carbon Sources for Nitrogen Removal. (EPA 832-F-13-016). Washington, DC: EPA Office of Wastewater Management.

4 Van Trump, JI., Wrighton, KC., Thrash, JC., Weber, KA., Andersen, GL., Coates, JD. (2011). Humic acid-oxidizing, nitrate-reducing bacteria in agricultural soils. Mbio 2.

5 Aero-Mod and Sequox are trademarks of Aero-Mod, Inc.

ProBiotic Scrubber® N is a registered trademark of BioLynceus® LLC

ProBiotic Scrubber® Candy Carbon® is a registered trademark of BioLynceus® LLC BioLynceus® is a registered trademark of BioLynceus® LLC

©Copyright September, 2020 by BioLynceus® LLC, all rights are reserved

[/et_bloom_locked]