Collection System 0.2 MGD

Wastewater collection systems are prone to accumulate high hydrogen sulfide (H2S) concentrations. Sulfatereducing bacteria (SRB) produce H2S in these systems in

the process of breaking down organic compounds under anaerobic conditions.1 Collection infrastructures are often ideal environments for SRB to grow in abundance.

Wastewater conditions such as, temperature, pH, conductivity, and flow rate (among others) have an impact on H2S production and gas emissions in these systems.

Excess H2S production can cause many challenges for wastewater managers. The gas has a strong unpleasant odor and can contribute to the corrosion of collection pipes, manholes, and other infrastructure components. Additionally, H2S can be hazardous to human life at high concentrations. To mitigate H2S, bioaugmentation can be used to limit SRB growth in collection systems.

Augmenting cultures of bacteria that can outcompete or inhibit SRBs can reduce H2S production in collection infrastructures. The following case study details the use of BioLynceus® ProBiotic Scrubber® OCC (PBOCC) to treat H2S in a collection system.

A municipality in Arizona was having issues with H2S levels in their lift stations and manholes. The gas was degrading the collection infrastructure and causing strong odors. After several residents in the area filed odor complaints, the management actively sought a solution to reduce H2S production.

The city decided to implement bioaugmentation to decrease SRB populations in the collection system. BioLynceus® PBOCC was inoculated in several of the wastewater lines to reduce H2S and associated odors. The product contained highly diversified live cultures of wastewater bacteria.

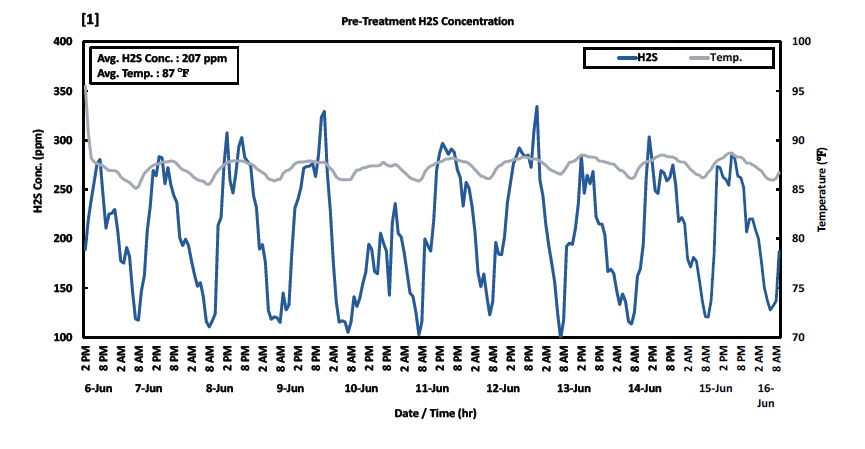

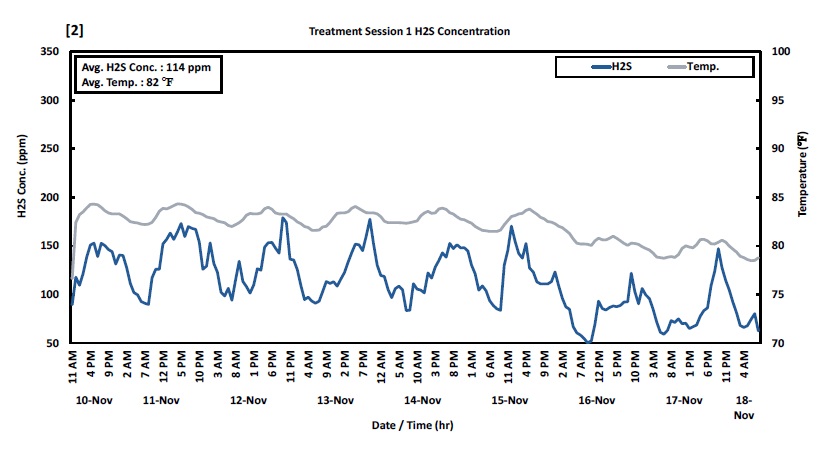

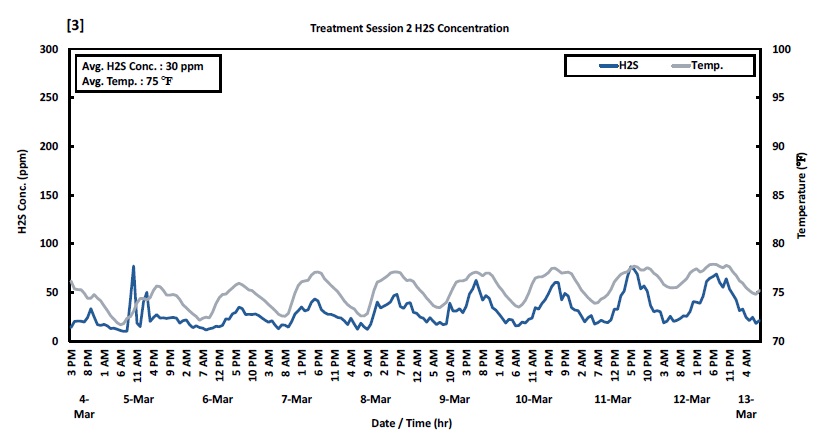

Figure 1. Hourly average H2S concentrations and air temperatures for line 1 of the collection system. Data was collected over three odalog sessions, [1] pre-treatment (November 6-16), [2] PBOCC treatment session 1 (November 10-18), and [3] treatment session 2 (March 4-13).

In line 1, the average H2S concentrations for the pretreatment session, and treatment sessions 1 and 2, were 207, 114, and 30 ppm. Average H2S was reduced by approximately 45% in the first treatment session, and 86% in the second. Furthermore, the air temperature decreased by seven degrees between sessions one and three and may have indicated a decrease in wastewater temperature.

Section 2.3.2.5 of the EPA design manual for odor and corrosion control of sanitary sewer systems and treatment plants (1985) reported, the rate of sulfide production by SRB increased seven percent/ degree water temperature increase up to 30°C .1 This

information considered, the decrease in wastewater temperature contributed to lowering the atmospheric H2S concentration.

However, the reduction of H2S from 207 ppm to 30 ppm is significant and not entirely a

result of temperature reduction alone.

During the PBOCC treatment, the city did not receive odor complaints. Using PBOCC helped decrease H2S concentrations and related issues in the collection system.

BioLynceus® ProBiotic Scrubber ® OCC helps reduce H2S production in collection systems.

1 U.S. Environmental Protection Agency (USEPA). (1985). Design manual for odor and corrosion control in sanitary sewerage systems and treatment plants. EPA/625/1-85/018, Center for Environmental Research Information, Office of Research and Development, Cincinnati.