Collection System 0.04 MGD

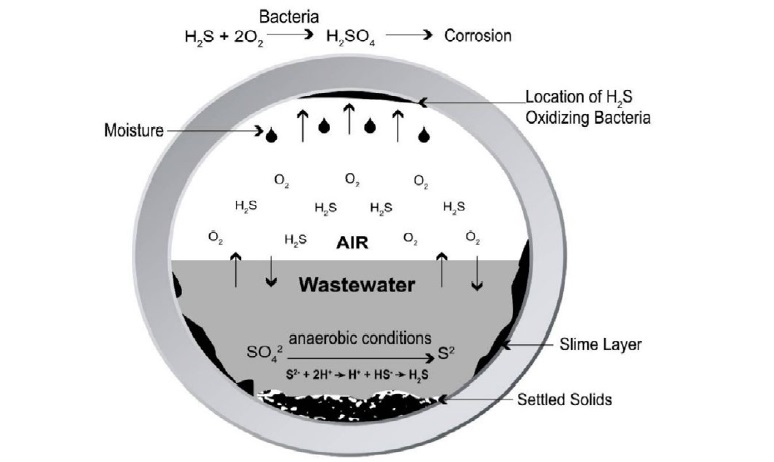

Hydrogen sulfide (H2S) is a noxious gas that can accumulate in collection systems. This gas forms when sulfate reducing bacteria (SRB) digest organic material under anaerobic conditions.1 Furthermore, H2S production is a prominent issue for wastewater utilities providing services in warm climates.

The oxygen in collection lines is consumed more rapidly at high temperatures,

which can create anaerobic conditions that are ideal for sulfide production.2 Wastewater utilities are motivated to reduce H2S emissions, because of the associated odors, infrastructure corrosion, and potential toxicity for sewer

workers.

Figure 1. Sulfide transformations in a gravity collection systems (Apgar & Witherspoon 2008).

Bioaugmentation can be utilized to limit H2S formation in collection systems. By implementing concentrated cultures of organotrophic bacteria in collection

infrastructures, SRB abundance can be limited, reducing H2S production. The following paragraphs outline a successful H2S treatment using BioLynceus® ProBiotic Scrubber® OCC (PBOCC).

A municipality in New Mexico was experiencing issues with high H2S concentrations in their collection infrastructure. The gravity collection system averaged 0.04 MGD flows which were discharged to a larger wastewater utility for treatment. Furthermore, H2S accumulation was greatest in the system force main.

Vapor measurements at the outfall of the line averaged 150 parts per million (ppm). To stay within the city’s limit, the H2S concentrations in the head space of the pipe needed to average 5 ppm or below. Because the force main was out of compliance for H2S and produced odors, the wastewater management needed to find a solution to reduce H2S formation in the line.

BioLynceus® bioaugmentation was recommended to the city to treat their H2S problem. Daily applications of a special blend of organotrophic bacteria, PBOCC,

were administered to the lift station ahead of the force main. This product helped add a diversified community of bacteria that would outcompete the SRB in the pipe.

PBOCC was applied for two months, March-April, until stable results were achieved. During this time, the average daily air temperature ranged between 50 and 70 °F. Within 60 days, H2S concentrations at the outfall of the force main were below city ordinance limits and malodors were reduced.

The wastewater staff reported the smell from the pipe had changed from pungent to earthy. An additional side benefit of treatment was, the lift station where product was dosed had less fats, oils, and grease residues than before treatment. Cleaning and maintenance requirements were reduced for the wet well.

Throughout the course of treatment, H2S concentrations and odors were decreased. Additionally, the force main H2S concentrations were brought in compliance with the city ordinance. The PBOCC treatment worked so well, the city continued to add product into the collection system.

BioLynceus® ProBiotic Scrubber® OCC helps reduce H2S production in collection infrastructures.

1 Gerardi, M. (2016). Wastewater Bioaugmentation and Biostimulation. Lancaster, Pennsylvania: DEStech Publications, Inc. Pp. 20-21.

https://www.amazon.com/Wastewater-Bioaugmentation-Biostimulation-Michael-Gerardi/dp/1932078789

2 Apgar, P.D., Witherspoon, J. (2008). Minimization of Odors and Corrosion in Collection Systems. IWA Publishing. Pp 7-10.

https://books.google.com/books/about/Minimization_of_Odors_and_Corrosion_in_C.html?id=dpg7NwAACAAJ&source=kp_book_description