The Power of Lagoon Systems

It is common knowledge that bacteria thrive in some environments better than others. Bacteria can only consume or degrade compounds they touch or attach to. One of the best systems to increase contact/retention time is a lagoon system.

Personally, I prefer lagoons because when properly designed and managed, they can provide as much as 40 to 75 days of contact time. Activated sludge systems can have as little as 3 to 7 days of contact time. It only stands to reason that more contact time enhances the biological process in wastewater systems. Increased contact time allows the bugs to reduce more solids, BOD, TSS, nutrients and other contaminants.

A common mistake I have seen over the years is lagoon systems with entirely too much aeration. Over-aeration causes solids suspension and prevents the bacteria from degrading these solids. Over-aeration can also contribute to increased sludge accumulation in the secondary and tertiary lagoon cells and create significant challenges in meeting discharge permits set forth by the National Pollutant Discharge Elimination System (NPDES).

If you are having these issues, you could start systematically reducing your aeration or mixing to achieve maximum efficiency of the biological process. Lagoons may be great for primary and secondary wastewater treatment, but they are not well suited for full BNR (biological nutrient removal). Although lagoon systems may nitrify well, there is usually no way to denitrify due to the lack of a controlled anoxic zone.

Additionally, biological phosphorous removal is usually not possible because there is no controlled anaerobic zone followed by an aerobic zone. To meet upcoming NPDES nutrient limits on phosphorous and nitrogen, most lagoon systems will need to add additional treatment systems or be abandoned and replaced with expensive mechanical bug hotels.

Solids Reduction

Solids handling is a major issue across the country today. The cost of wasting, dredging, de-watering, permitting, hauling and disposal are increasing every year. It only makes sense that the better biodegradation we get in our wastewater systems the less it will cost to handle these solids. Biologically reducing solids is environmentally sustainable because it reduces the impact of the landfilling or land-applying the material.

Biological enhancement of your facility produces fewer solids and saves money in the process. Bacteria will not eat sand, silt, or clay, but they are very good at breaking down organic compounds. Almost anything with carbon in its molecular structure is biodegradable. What you want to accomplish determines which bacteria you should use.

With all the changing conditions in your system, it is becoming more and more important to optimize your wastewater processes with the addition of live bacteria (bioaugmentation). Even wastewater plants that seem to be working well can often benefit from the addition of live bacteria. Live cultures may be needed to increase the reduction of biosolids, BOD, TSS, nutrients, foaming and chemicals.

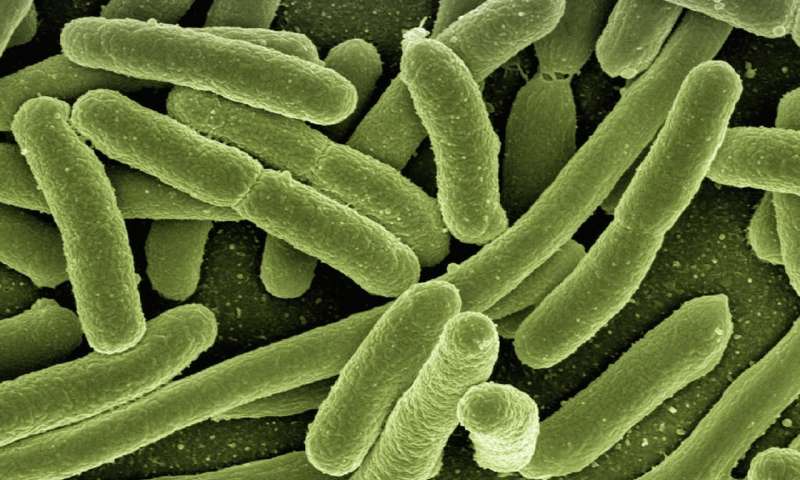

Figure 1. A close up of microbes that are responsible for removing pollutants from wastewater. Image retrieved from https://phys.org/news/2017-12-scientists-microbes-memories-environment.html

Biostimulation and Bioaugmentation

Biostimulation can be used to optimize wastewater treatment and is available in many different forms. A common form of biostimulation is adding food (external organic carbon) to feed the bacteria. This is a common practice in months of low flow or when treating highly variable industrial waste from significant industrial users (SIUs).

When operators see a reduction in food to microorganism ratios (F:M) they may choose to add food. Things I have seen used include sugar, molasses, dog food, pig food, methanol, and brewers waste. I do not recommend ever using dog food because it is loaded with fats, oils and grease (FOG).

If you want to supplement your system with a cheap animal food, I recommend using pig food instead. However, the best possible option is our product Candy Carbon®.

Another form of biostimulation is adding products to change the consistency of materials in the wastewater stream. Examples of this include adding citric and chemical degreasers and even enzymes (commonly sold as catalytic enzymes). Catalysts are used to change the substrate to a liquid that microbiology can degrade.

One problem I see with enzymes is each one is very specific to the substrate it reacts with. If you do not have the correct bacteria to consume the liquefied substrate, the enzymes could be of no value. If the specific substrate is not available, the enzyme will not work. Always remember there is a difference between buying enzymes for biostimulation and buying bacteria for bioaugmentation.

The same thing is true of degreasers. If bacteria populations are not large enough to degrade all the grease when it is liquefied, the FOG just travels downstream and re-coagulates. If a significant inflow of liquid FOG hits your headworks, it could result in massive foaming issues due to filamentous bacteria that may be present in your system. If you encounter a foaming issue, a bioaugmentation program may be required to out-compete the filamentous bacteria and get your facility back on track.

In the world of bioaugmentation, I recommend using only liquid live cultures. Look for products with high CFU (colony forming units) and high SRD (species richness diversity), or better yet, a highly concentrated consortium of life forms (microbial soup) that have a long shelf life and do not require special handling such as refrigeration. Make sure you know what you are buying, and that the supplier is reputable.

Wrapping Up

In conclusion, bioaugmentation and biostimulation are viable solutions for many of your systems and are still some of the least expensive options to try. To reiterate, when given several options, doesn’t it make sense to try the least expensive solutions first? If you think bioaugmentation or biostimulation might be a solution for your system, let us know how we can help you decide which products to use to meet your needs. If you have any questions, want additional training for your organization, or need more assistance, contact me at rick@biolynceus.com

Rick Allen© BioLynceus®