Treatment plant managers and operators know the challenges of developing and maintaining the correct population and balance of organisms for optimizing the biological wastewater treatment process. It’s a daily challenge to maintain the right balance of organisms and nutrients to provide a clean and safe effluent to discharge back to the environment.

The challenge becomes even greater with startup of new or newly renovated treatment systems. This is the story of how three such systems successfully used ProBiotic Scrubber®II from BioLynceus® to speed and simplify this process.

1 MGD IFAS System Ready to Receive Full Influent Load in 10 days

A wastewater treatment facility in Colorado, serving a population of 6,600 people, needed an upgrade. The original mechanical plant was built in 1956 and was last upgraded in 1985. In 25 years, the plant had deteriorated to the point where the effluent ammonia levels were exceeding permit limits…

This was an issue because their effluent was released to the Arkansas River, an essential water resource for downstream farmers and municipalities. To get the plant discharge back in compliance, the management of the facility decided to add on a new treatment train to the existing system. The owner and consulting firm agreed to construct a 1 MGD integrated fixed-film activated sludge (IFAS) process.

After construction was completed, the system needed to be seeded with the proper biology for efficient treatment. The operators hesitated to seed the new IFAS process with activated sludge from the old plant. They did not want to transmit the same treatment issues from the existing system to the new one. Because of logistical concerns and expenses, the project engineer decided to use BioLynceus® PBII to startup the plant. The IFAS process was inoculated with PBII in the aeration basin under low flow conditions. After 10 days of treatment, the biomass in the new process had aggregated and was ready to start processing the full influent load.

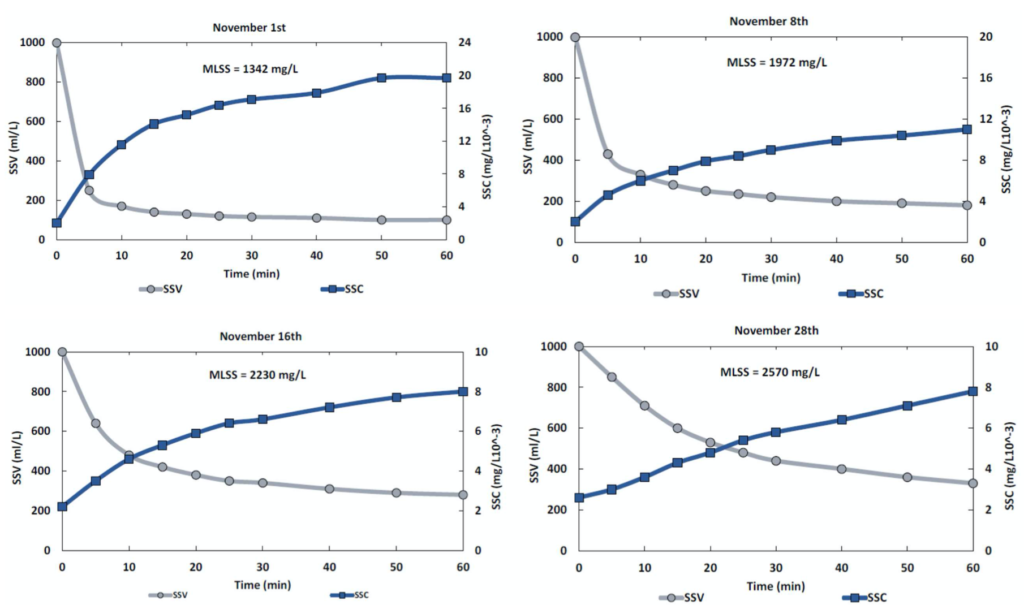

Settleometer testing was conducted throughout the first month of IFAS system operations. The results from the settleometer tests showed SSV decreased over time and SSC increased. These trends indicated proper settling in the aeration basin. SVI values were calculated from the 30- minute SSV for each settleometer test. The averaged SVI number in the first month of operations was 130 ml/g which was under the threshold for a poor settling.

Results of Settleometer Testing

After adding PBII for a month, the operations reports showed that the clarifiers were fully functioning, and discharge was within NPDES limits. The PBII treatment provided the facility with an optimal biomass for wastewater processing.

Startup Mechanical Plant After Failed Activated Sludge Seeding

Choosing an appropriate seeding method for wastewater operations can have a significant impact on biological treatment efficiency. Activated sludge is traditionally used to seed new treatment systems and supplement others that need bioaugmentation. A common issue in activated sludge systems is sludge bulking (SB), or the uncontrolled growth of filamentous bacteria (FB). Impacts of a bulking sludge include (but are not limited to) poor settleability, impaired biological nutrient removal, and increased facility maintenance.

Predicting whether SB will occur in a newly seeded wastewater process is difficult, because the FB in activated sludge respond differently to varying system conditions. One method to prevent bulking is to quantify the proportion of FB in activated sludge before inoculation. Previous studies have found that SB can occur in systems with a volume fraction of FB as low as 1-20%.

Even when filament forming organisms are in low abundance, they can still cause treatment issues. Bioaugmentation with a specifically designed microbial community can be a more reliable alternative to using activated sludge as seed. The following case study outlines the use of ProBiotic Scrubber® II (PBII) in a 0.7 MGD mechanical wastewater treatment plant (MWTP) to restore a healthy biomass after the plant was seeded with FB.

Wastewater from a small resort town in Colorado was processed at a mechanical plant with rotating bed contactors for nutrient removal. The plant included Evoqua disc filters for tertiary treatment. The plant was operating properly until a concentrated load of petroleum based toxic waste was introduced to the system. The biological treatment was severely inhibited by this event. Reseeding the biomass was necessary.

The facility operators brought in several loads of activated sludge from a neighboring wastewater treatment facility. What the operators didn’t know was the FB in the activated sludge seed would lead to nearly immediate problems.

Shortly after inoculation, the plant experienced undesirable foaming, solids settling, and clogged disc filters. 24-hour staffing was required just to keep up with backwashing the filters. After examining a mixed liquor sample from the plant, the head operator realized that FB accumulated in the reactor and were preventing solids and nutrient reduction from occurring. They needed to decrease the abundance of these organisms to resume proper wastewater processing. The facility management contacted BioLynceus® to provide a bioaugmentation plan to reinstate a healthy biological community in the treatment system.

BioLynceus® PBII was applied to the aeration tank of the 0.7 MGD system. Twenty-four hours after PBII was added, nitrification was restored in the basin. Suspended solids were gradually reduced in the plant effluent over several weeks. This indicated that the biology in the facility was shifting to a more desirable composition; and, improved settling. Foaming was reduced in the aeration basin to normal amounts (Figure 2). The operators were relieved to see such rapid improvement in the biological treatment. Abnormal disc filter clogging was eliminated. The facility had to meet stringent NPDES permit limits before discharge into the Blue River.

After treating the MWTP with PBII, the system established a better settling and healthier biomass for processing influent wastewater. The facility now keeps PBII on hand to restart the plant instead of hauling activated sludge.

Startup of a 0.06 MGD Membrane Reactor

National parks attract millions of visitors each year. Increased seasonal traffic experienced by these national treasures can overload the wastewater treatment infrastructure leading to treatment inefficiency and, eventually, structural replacement. When starting up a new plant, seeding with a healthy biomass is vital for instilling long-term treatment efficiency. Probiotic Scrubber® II (PBII) and small amounts of activated sludge were utilized to startup a membrane bioreactor (MBR) at a facility that experienced significant seasonal flow variations.

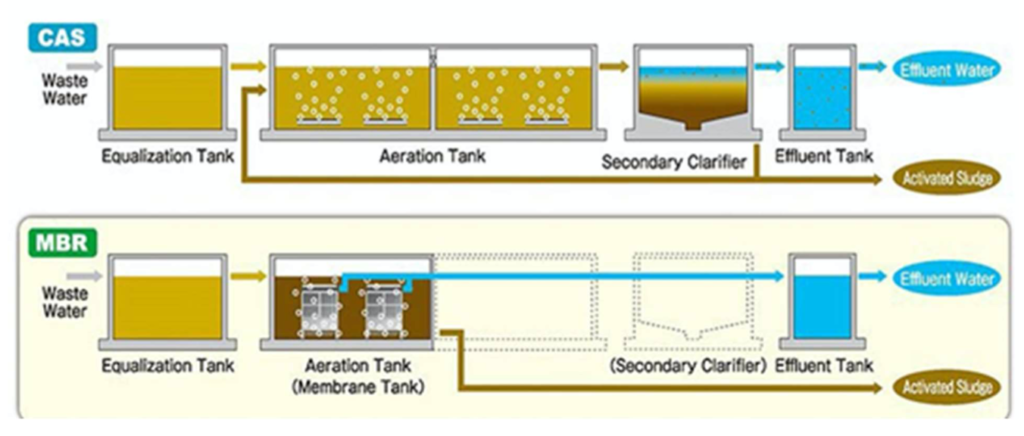

A national park in Wyoming was installing a new 0.06 MGD Kubota manufactured MBR system (Figure 3) to replace their old and overloaded conventional activated sludge (CAS) plant.

The quantity of wastewater processed by the CAS plant increased each tourist season, May to October. The high flows generated by the transient populations at the park frequently overwhelmed the facility. The mechanical plant received flows exceeding the small system’s treatment capacity. The effluent quality was declining, and the facility operators were concerned with meeting their NPDES permit limits.

Plant management decided their infrastructure needed to be replaced with a system which could handle higher flows (Figure 4). Designing and building the new MBR facility would take a minimum of two years. During that time, the current plant was required to meet permit limits. The Utilities Supervisor at the Park contacted BioLynceus® to design a bioaugmentation plan to improve the biological treatment efficiency of their old system. The Park used PBII at the CAS facility while the new MBR was constructed. PBII provided the biology needed to process high flows and keep the plant within permit compliance.

When the time came to startup the MBR facility, the management at the plant decided to use a combination of PBII and activated sludge to seed the reactor. Maintaining a high treatment efficiency was essential when starting up the new plant, so they opted to add PBII into the system from the beginning. Adding BioLynceus® product, reduced their sludge hauling costs, because they needed less activated sludge to start the reactor. From startup, the MBR system was properly processing influent wastewater. Seeding the reactor with PBII was cost effective and established a biomass that promoted efficient treatment in the new MBR treatment system.

ProBiotic Scrubber II is a registered trademark of BioLynceus® LLC BioLynceus® is a registered trademark of BioLynceus® LLC ©Copyright August 2020 by BioLynceus® LLC, All rights are reserved

[/et_bloom_locked]