Activated Sludge Plant 0.2 MGD

For many municipal wastewater treatment facilities, removing inorganic nitrogen to permitted discharge levels is a challenging requirement. Without the role of biological nutrient removal (BNR) in treatment systems, effluent wastewater will have high concentrations of nitrogenous species. Specifically, discharging nitrate loads into surface waters can have adverse impacts on aquatic environments, including eutrophication and toxic algal growth. Because of this, wastewater facilities are obligated to keep their biological treatment functioning properly.

For denitrification to proceed efficiently, there are several environmental conditions wastewater treatment facilities must maintain. These conditions include, sustaining an adequate abundance of denitrifying bacteria (DB) in a biomass, forming an anoxic zone, and having consistent organic carbon inputs to the anoxic process. DB must be present in the anoxic zone for nitrate removal to occur. These organisms need a stable low oxygen environment to reduce nitrate to nitrogen gas. Organic carbon availability in the anoxic process is a limiting factor for denitrification.1

Internal carbon substrate is often exhausted in the aeration process in activated sludge systems leaving very little to support denitrification. Previous studies have found that augmenting external organic carbon is necessary to achieve optimal nitrate removal.2

BioLynceus® provides an alternative organic carbon source, Candy Carbon® (CC), to fuel BNR. The following case study summarizes the use of CC at a 0.2 MGD activated sludge plant (ASP).

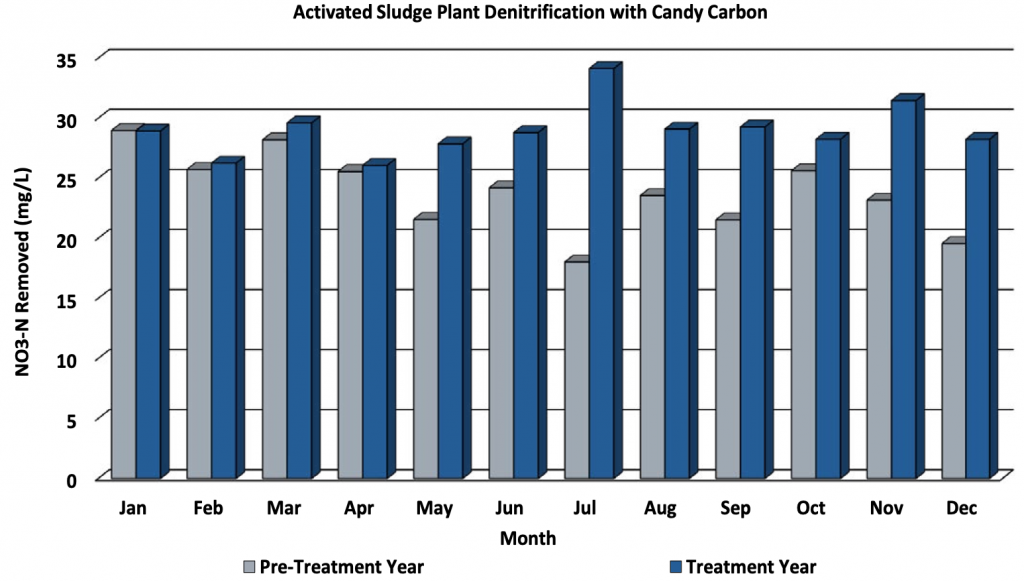

Figure 1. Monthly nitrate as N (NO3-N) removed from the ASP anoxic basin was determined for two years, with (blue) and without (grey) CC treatment.

The ASP was not facilitating denitrification in the secondary treatment basin. To avoid permit violations for nitrate, the plant operators started supplying the system with daily doses of CC. Product was applied to the anoxic zone where DB were reducing nitrate in the wastewater.

Within days, the concentrations of nitrate in the facility’s effluent were significantly decreased. The monthly concentration of nitrate removed was increased during CC treatment (Figure 1). The greatest monthly increase in removal experienced between the pre-treatment and treatment years was in July, 16 mg/L, and the least was in January, 0 mg/L. Candy Carbon® helped improve denitrification at the ASP.

BioLynceus® Candy Carbon® provides a quality organic carbon source for denitrification.

1 Gerardi, M. (2006). Wastewater Bacteria. Hoboken, New Jersey: John Wiley & Sons, Inc.Pp.86. https://www.amazon.com/Wastewater-Bacteria-Michael-H-Gerardi/dp/0471206911/ref=sr_1_1?dchild=1&keywords=wastewater+bacteria+gerardi&qid=1586290177&s=books&sr=1-1

2 United States Environmental Protection Agency (EPA). (2013). Wastewater Treatment Fact Sheet: External Carbon Sources for Nitrogen Removal. (EPA 832-F-13-016). Washington, DC: EPA Office of Wastewater Management. https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P100IL8F.TXT