Mechanical Plant Collection System 0.3 MGD

Fats, oils, and grease (FOG) build-up in wastewater collection lines is a persistent issue that has plagued many municipalities. Challenges arise when FOG and solids cause blockages in the transport pipes carrying influent flows to local treatment facilities. As greasy residues and solids accumulate, line jetting is often performed to eliminate troublesome build-ups. This option is expensive and time consuming.

According to the US Environmental Protection Agency, the cost of hydro-flushing one foot of pipe ranges between $0.32 and $1.00.1 Bioaugmentation can also be used to degrade greasy residues in collection infrastructure. When challenged with excess FOG in their collection system, a small sanitation district in Colorado used BioLynceus® ProBiotic Scrubber® II (PBII) to effectively reduce build-ups.

The collection lines ahead of the 0.3 MGD mechanical wastewater treatment facility were clogged by accumulated sludge and FOG. If the buildup was left untreated the line could back-up causing a sanitary sewer overflow. Before jetting the lines, the sanitation district decided to try bioaugmentation to degrade the FOG. In need of a cost-effective, biological solution, the sanitation district management contacted BioLynceus®.

They began augmenting their system with PBII in two of the main collection pipes. The PBII treatment implemented concentrated, live cultures of wastewater bacteria to break down the problem build-ups.

The bioaugmentation plan reduced FOG and sludge in the collection lines. The sanitation district supervisor explained, he did not need to jet the lines after using PBII in the collection system. Additionally, PBII helped to reduce the quantity of wasted solids at the wastewater treatment plant.

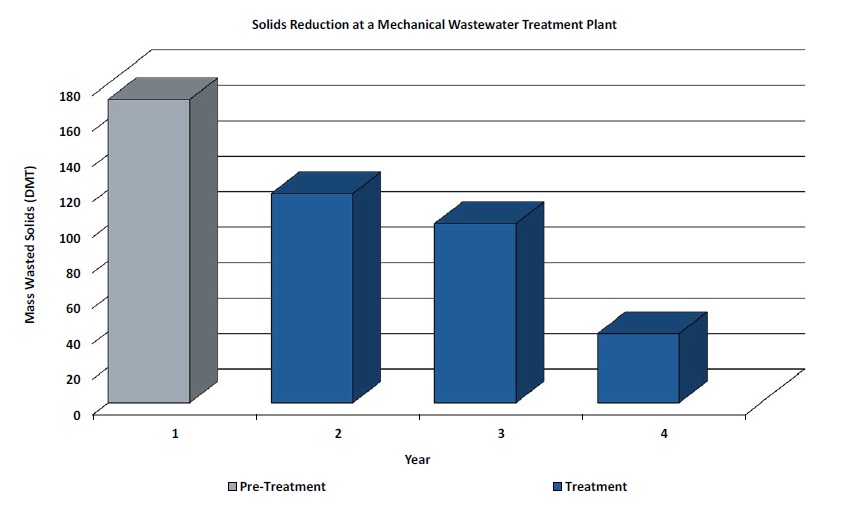

Figure 1. Average annual wasted solids from the aerobic digester at a mechanical treatment plant were determined for the year prior to adding PBII (grey) and three years during treatment (blue). Wasted solids values were calculated in dried metric tons (DMT).

A side benefit of treating the collection system with PBII, was the quantity of disposed solids in the down line wastewater treatment plant digester decreased. The solids mass dried and vacated (SMDV) from the aerobic digester was reduced by 31% in the first year. After the second and third years of treatment, the SMDV was decreased by 14% and 61%.

By reducing biosolids in the digester, bioaugmentation helped the facility save over $20,000 in removal fees in the first year. Wasted solids management at wastewater treatment plants can be time consuming and expensive. The Environmental Protection Agency estimated the expense of biosolids handling and disposal made up 40% to 60% of the annual cost for treatment plant operations.2

Improving biological solids degradation at the mechanical plant reduced the financial burden of wasted solids hauling and disposal. Augmenting the collection system with BioLynceus® cultures helped reduce FOG in the collection lines, solids in the digester, and minimized biosolids management and jetting costs.

BioLynceus® ProBiotic Scrubber® II helps reduce solids and FOG in wastewater treatment.

1 Collection Systems. O&M Fact Sheet. Sewer Cleaning and Inspection (1999). United States Environmental Protection Agency. Office of Water, Washington, D.C. https://www3.epa.gov/npdes/pubs/sewcl.pdf

2 U.S. Environmental Protection Agency. (1985). Estimating Sludge Management Costs Handbook. Cincinnati, OH: Center for Environmental Research Information. https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=30004B0L.TXT