Mechanical WWTP 2 MGD

Many wastewater systems experiencing high infiltration and inflow (I&I) have issues with hydraulic overloading which impacts biomass stability. I&I can impair the capacity of the wastewater collection system and wastewater treatment infrastructure.

Increased flows in the collection system contribute to hydraulic overloading at wastewater treatment facilities. This disrupts the biological treatment process by diluting the organic carbon supply to the biomass at the plant. Without a high strength organic food supply, the growth and metabolism of wastewater processing microorganisms are inhibited.

Wastewater treatment facilities may struggle to stay in compliance with state and federal water quality standards due to high I&I. The following case study details the application of Candy Carbon® (CC) at an activated sludge plant (ASP) to improve biomass stability after I&I washouts.

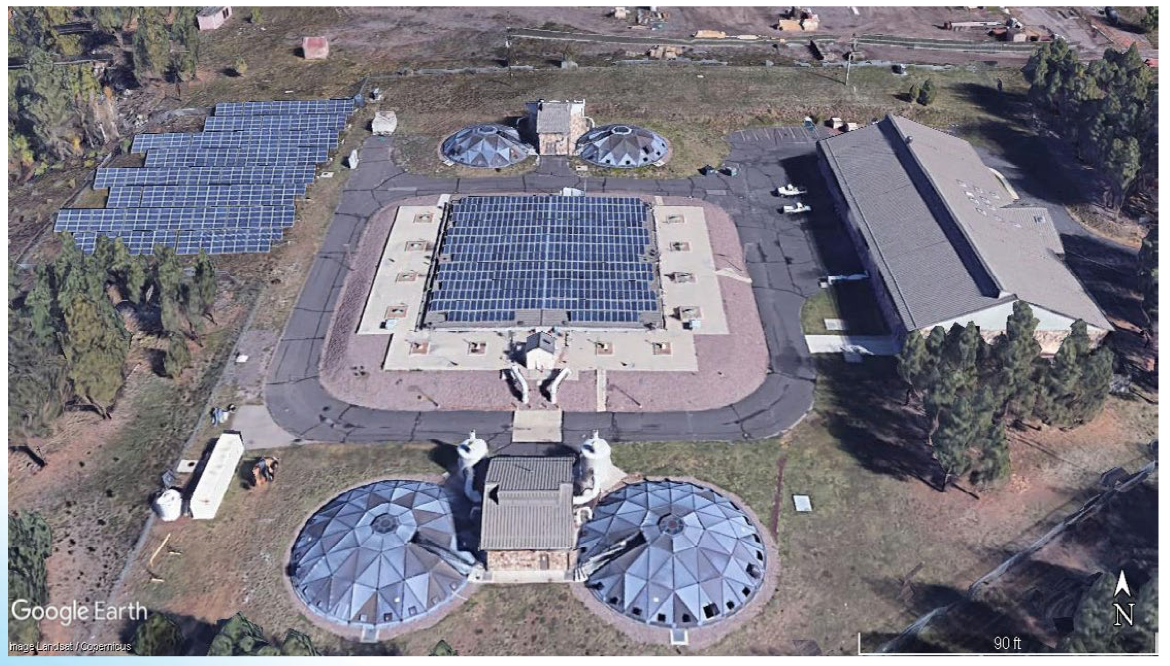

Figure 1. Google Earth Image of the 2 MGD ASP experiencing washout events due to I&I.

A 2 MGD ASP in a mountainous area in Arizona was having trouble processing wastewater after large precipitation events and during spring snow melt. After a surge of storm or melt water entered the system, the organic carbon levels would decrease and starve the biology in the treatment process.

The facility operators suspected that their system was experiencing increased I&I following these events. In order to sustain the biological treatment at the plant, the facility staff added an organic carbon source to their returned activated sludge (RAS) stream.

The first product they used required a very high application rate and had minimal impact on increasing the biomass in their system. Seeking a new organic carbon supplement, the Plant Supervisor contacted the wastewater experts at BioLynceus®.

The ASP began injecting CC into their RAS during periods of increased I&I. After the first two applications of CC, the facility operators were impressed with how quickly their biomass recovered from the washouts. They needed to add less product than ever before to get their biological treatment up and running.

The head wastewater operator at the plant explained that they applied 75% less CC than the previous product used. Because of this, injecting CC was much easier and less time consuming than implementing the prior treatment.

BioLynceus® helped minimize storage space, application time, and treatment recovery time. CC provided the wastewater system with an adequate organic carbon source to support the biomass in instances of elevated I&I. The facility continues to use CC in the winter and spring months to improve the efficiency of their biological process.

BioLynceus® Candy Carbon® provides organic carbon to support wastewater biomass.

1 National Small Flows Clearinghouse West Virginia University. (1999, spring). Infiltration and Inflow can be Costly for Communities. Pipeline, 10(2), 1-8. http://www.nesc.wvu.edu/pdf/WW/publications/pipline/PL_SP99.pdf